Hdg High Tensile Bolts Grade 8.8

Product Details:

- Corrosion Resistant Yes, due to HDG finish

- Drive Type Hex Drive

- Shape Hex Head

- Standard IS 1363 / IS 1364 / DIN 933 / DIN 931

- Head Type Hexagonal

- Feature High Strength, Durable, Corrosion Resistant

- Load Capacity Designed for high-tensile applications

- Click to View more

X

Hdg High Tensile Bolts Grade 8.8 Product Specifications

- 26 - 32 HRC

- Metric, Coarse Threaded

- M6 to M64

- 8.8

- Alloy Steel

- High Load Bearing

- Hot Dip Galvanized (HDG)

- Zinc Coated / Galvanized

- Bolt

- 800 MPa (minimum)

- Construction, Bridges, Heavy Machinery, Structural Steelwork, Industrial Assembly

- Designed for high-tensile applications

- Hexagonal

- High Strength, Durable, Corrosion Resistant

- 0.01 mm

- IS 1363 / IS 1364 / DIN 933 / DIN 931

- Hex Drive

- Yes, due to HDG finish

- As per grade 8.8 torque rating

- Hex Head

- As per standard or customized

Product Description

Hdg High Tensile Bolts Grade 8.8

| Size | M 8 TO M 24 |

| Surface Treatment | Hot Deep Galvanizing |

| Material | High Tensile |

| Coating | Galvanising |

| Usage/Application | Construction |

| Brand | VI,IMPORTED |

| Grade | 8.8 |

| Quantity Per Pack | DEPEND ON SIZES |

| Packaging Size | Bags, Boxes |

| Country of Origin | Made in India |

Additional Information:

- Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch: MUMBAI

- Production Capacity: 25000 KG MONTHLY

- Delivery Time: 4 - 6 WEEKS

- Packaging Details: AS PER CUSTOMER REQUIREMENT

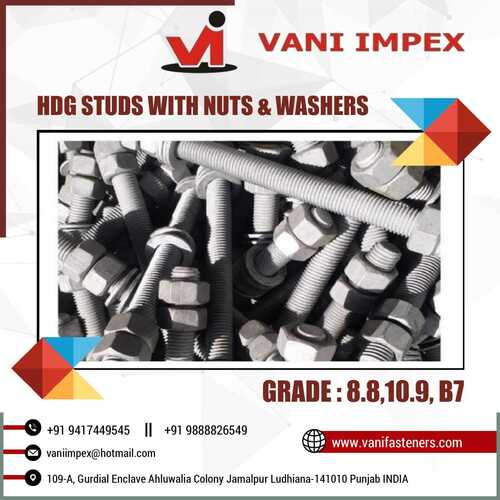

Exceptional Strength and Durability

Built with Grade 8.8 alloy steel and a hardness of 26-32 HRC, these bolts deliver a minimum tensile strength of 800 MPa. This ensures safety and stability for demanding environments, providing high load-bearing capacity for critical assemblies.

Superior Corrosion Resistance

The hot-dip galvanized (HDG) surface treatment enhances protection against rust and environmental wear. Ideal for both indoor and outdoor installations, these bolts maintain integrity even in harsh conditions, ensuring long-term reliability.

Versatile Applications and Customization

With length options from 10 mm to 500 mm, diameter range M6 to M64, and adherence to IS/DIN standards, these bolts meet diverse requirements across construction, bridges, industrial machinery, and structural steelwork. Custom thickness and packaging options are available to suit project needs.

FAQ's of Hdg High Tensile Bolts Grade 8.8:

Q: How are the Hdg High Tensile Bolts Grade 8.8 manufactured?

A: These bolts are produced using forged and machined processes to ensure precise dimensional accuracy and high structural integrity. Their surface is hot-dip galvanized for corrosion resistance.Q: What environments are suitable for using these bolts?

A: They are designed for both outdoor and indoor use, making them ideal for construction, bridges, heavy machinery, and other industrial applications given their resistance to corrosion and temperature extremes.Q: Where are these bolts typically applied?

A: Common applications include structural steelwork, industrial assembly, bridge construction, and heavy machinery installations, thanks to their high load-bearing capacity and durability.Q: What are the storage conditions required for these bolts?

A: To maintain optimal quality, store the bolts in a dry, cool place protected from moisture and contaminants, preventing any reduction in corrosion resistance.Q: When should I choose Grade 8.8 bolts with HDG finish over other fasteners?

A: Choose these bolts when you require high strength, excellent corrosion resistance, and reliable performance in demanding environments or high-tensile applications.Q: What are the benefits of the hot-dip galvanized finish on these bolts?

A: The HDG finish provides superior corrosion resistance, extending the lifespan of the bolts even in aggressive industrial or outdoor environments, thus reducing maintenance and replacement costs.Q: How does compliance with IS and DIN standards benefit users?

A: Compliance ensures consistent quality, performance, and compatibility with global engineering requirements, facilitating safe and standardized installations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS