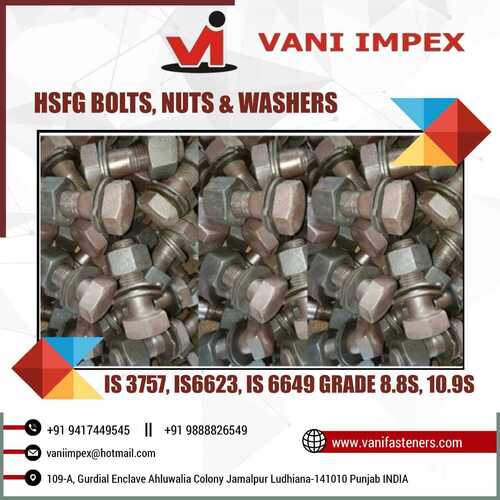

High Strength Friction Grip Bolts

Product Details:

- Grade 8.8, 10.9, 12.9

- Finish Smooth, Rust Resistant

- Load Capacity Up to 150 kN (varies with diameter and grade)

- Surface Treatment Hot Dip Galvanized, Black Oxide, Phosphated

- Standard IS 3757, IS 6623, EN 14399, ASTM A325/A490

- Feature High Strength, Fatigue Resistant, Precise Tolerance

- Thickness As per design specifications

- Click to View more

High Strength Friction Grip Bolts Price And Quantity

- 130.00 - 180.00 INR/Kilograms

- 1000 Kilograms

High Strength Friction Grip Bolts Product Specifications

- Friction Grip Bolt

- 8.8, 10.9, 12.9

- +/- 0.01 mm

- Up to 150 kN (varies with diameter and grade)

- Alloy Steel

- Bridges, Steel Structures, Transmission Towers, Heavy Engineering

- Smooth, Rust Resistant

- Wrench Drive (External Hex)

- Hot Dip Galvanized, Black Oxide, Phosphated

- IS 3757, IS 6623, EN 14399, ASTM A325/A490

- High Strength, Fatigue Resistant, Precise Tolerance

- Metric Coarse Thread

- Cylindrical with Hexagonal Head

- Hexagonal Head

- Yes, with protective coatings

- 250850 Nm (as per size and grade)

- As per design specifications

- 830-1040 MPa

- 2834 HRC

- M16 to M36 (custom sizes available)

- High load bearing capacity for structural assemblies

Product Description

High Strength Friction Grip Bolts

|

Property Class |

8.8S,10.9S |

|

Standard |

IS 3757, IS 6623, IS 6649 |

|

Bolt Type |

High Strength Friction Grip Bolts (HSFG Bolts) |

|

Grade |

8.8S,10.9S |

|

Packaging Type |

BAGS/BOXES |

|

Size |

M 16 TO M 42 |

|

Brand |

VI |

|

Material |

EN-18, EN-19 |

We are involved in supplying a wide assortment of HSFG Bolts Nuts And Washers. Our offered products are manufactured using high grade raw material that is procured by us from the authentic vendors, who hold aprominent position in the market. These products are checked against various parameters under the strict supervision of adroit professionals to ensure flawless supplies. In addition to this, these products are highly acknowledged in the market for their resistant to corrosion & temperature and high tensile strength.

Features:

Made with precision

Ruggedness

Anti-corrosive nature

Specifications:

Bolt:(IS-3757) Grade- 8.8S, 10.9S

Nut:(IS-6623) Grade- 8S, 10S

Circular Washer: (IS-6649)

Grades: 8.8S, 10.9S

Finishing: Blackodise, White Zinc Plated, Yellow Zinc Plated, Hot Dip Galvanized

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: BOXES, BAGS

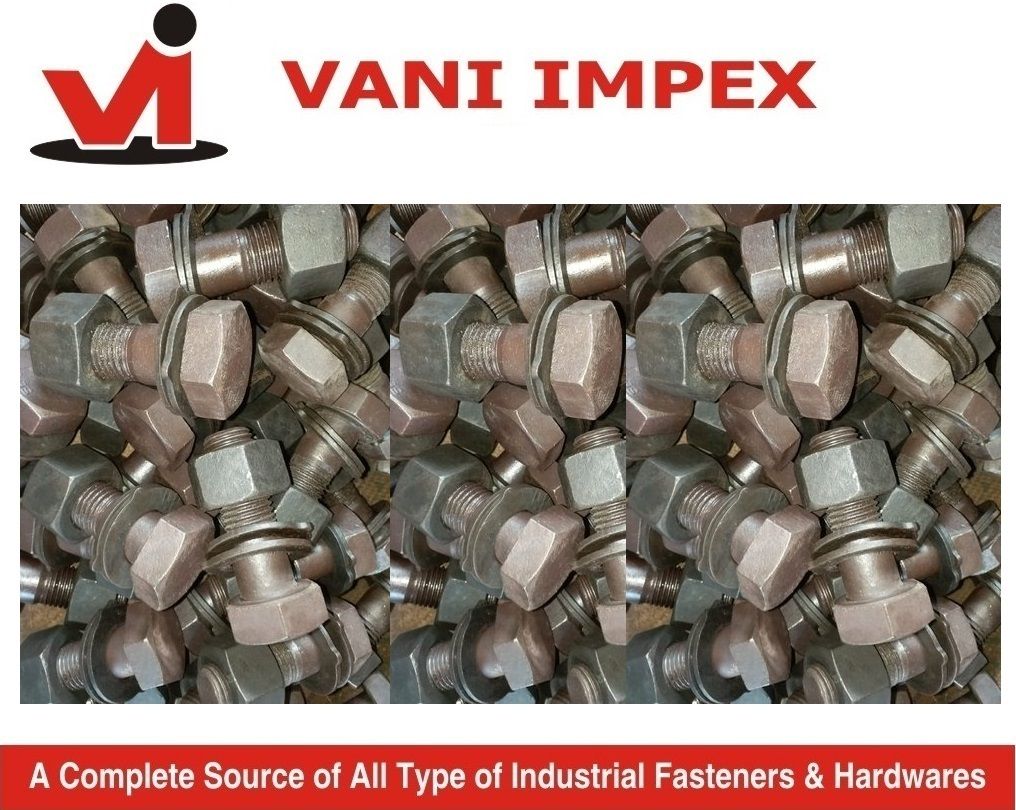

Built for Demanding Structural Use

These bolts are specifically designed for high load-bearing capacity and precise tolerance in critical structural assemblies. Their robust construction and advanced surface treatments deliver reliable performance in bridges, heavy steel frameworks, and transmission towers exposed to high stress and environmental extremes.

Versatile Sizes and Customization

With diameters from M16 to M36 and lengths up to 300 mm, clients can specify full or partial thread lengths as per project requirements. Custom manufacturing ensures a precise fit for a wide variety of engineering applications, maximizing both safety and efficiency.

Certified Safety and Longevity

Each bolt complies with global industry standards like IS 3757, EN 14399, and ASTM A325/A490, and holds CE and ROHS certifications. The combination of cold forging, heat treatment, and protective coatings guarantees long-term durability, corrosion resistance, and optimal safety in harsh environments.

FAQ's of High Strength Friction Grip Bolts:

Q: How are High Strength Friction Grip Bolts packaged for delivery?

A: All bolts are packed in export-quality wooden cases or cartons to ensure safe shipment and protection from damage or corrosion during transit.Q: What environments are these bolts suitable for, and how do they perform under extreme conditions?

A: These bolts are engineered for outdoor and high-stress environments, withstanding temperatures from -20C to +350C. Advanced surface treatments like hot dip galvanization and phosphating provide robust corrosion and rust resistance.Q: What is the manufacturing process for these friction grip bolts?

A: The bolts are manufactured through a cold forging process followed by precision heat treatment, which enhances their mechanical strength, fatigue resistance, and load-bearing capacity.Q: When should I choose full or partial thread bolts for my project?

A: Selection depends on load requirements and assembly specifics. Full thread bolts offer superior grip along their entire length, while partial thread bolts are preferred where shear strength and alignment at the shank are critical.Q: Where are these bolts commonly used?

A: They are primarily used in infrastructure applications including bridge construction, steel building frameworks, transmission towers, and other heavy engineering projects requiring high mechanical performance and safety.Q: What are the benefits of using these bolts in structural assemblies?

A: Key benefits include high tensile and proof load strength, fatigue resistance, precise tolerance (+/- 0.01 mm), rust protection, and compliance with major international standards, ensuring both safety and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS