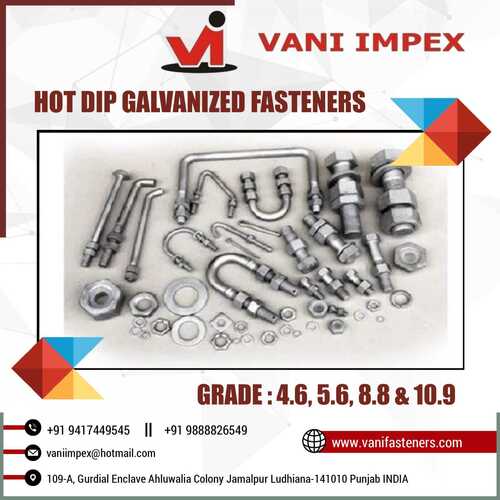

High Tensile Bolts and Nuts

Product Details:

- Hardness 28-45 HRC

- Shape Hex

- Grade 8.8, 10.9, 12.9

- Corrosion Resistant Yes

- Head Type Hexagonal

- Thread Type Metric, UNC

- Load Capacity Heavy Duty

- Click to View more

High Tensile Bolts and Nuts Price And Quantity

- 130.00 - 180.00 INR/Kilograms

- 1000 Kilograms

High Tensile Bolts and Nuts Product Specifications

- 28-45 HRC

- High strength, Precision engineered

- Yes

- Automotive, Construction, Engineering, Machinery

- Up to 250 Nm

- 800-1200 MPa

- 8.8, 10.9, 12.9

- 0.02 mm

- Hex

- Black oxide, Zinc plated, Hot dip galvanized

- Heavy Duty

- Metric, UNC

- Polished, Electroplated

- Bolt and Nut

- Hexagonal

- Up to 100 MT/month

- Alloy steel, Carbon steel

- M6 to M48

- Custom as per requirement

- External Hex

- ISO 898, DIN 931, DIN 933, IS 1367

Product Description

High Tensile Bolts & Nuts

|

Size |

M 6 TO M 24 |

|

Brand |

VI OR IMPORTED |

|

Quantity Per Pack |

DEPEND ON SIZE |

|

Usage/Application |

Industrial |

|

Packaging Type |

CARTON OR BAGS |

|

Grade |

8.8,10.9 |

|

Bolt Head Shape |

HEX |

|

Hardness |

28 - 32 |

We offer a comprehensive range of High Tensile Bolts and Nuts in order to meet various industrial requirements. Our products are offered in diversity of grades and sizes with the highest quality. As these are widely demanded by the client from different industries, we stock Bolts &Nuts in bulk quantities.

Being a prominent supplying and exporter Bolts and Nuts are resistant and corrosion. Bolts and Nuts finds its application in machinery or fabrication required for high strength. These Bolts and Nuts are extremely durable, reliable and are widely used in different industries.

Availability

Sizes : M3 to M36

Length : Up to 250

Material grades : 8.8GR, 10.9GR, 12.9 GR

Features

High Tensile Strength

Black odised Finish

Wear and Tear Resistant

High Stress Bearing

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: CARTON BOX OR GUNNY BAG

Precision and Strength You Can Rely On

Our high tensile bolts and nuts are CNC machined to precise tolerances, ensuring perfect fit and reliability in every assembly. Designed for a wide range of industrial and structural workloads, they guarantee strength and performance even in the most demanding environments. Manufactured to meet ISO and DIN standards, each fastener delivers consistent quality, heavy-duty load capacity, and corrosion resistance, giving you peace of mind for critical installations.

Versatile Applications Across Industries

From automotive and construction to engineering and machinery, our bolts and nuts are suitable for a vast array of heavy-duty fastening requirements. Their multi-grade options (8.8, 10.9, 12.9), combined with robust finishes and rust-resistant properties, make them a trusted choice for both new builds and maintenance activities. Available in custom thicknesses and finishes, they adapt easily to diverse project needs.

FAQ's of High Tensile Bolts and Nuts:

Q: How are the high tensile bolts and nuts manufactured to ensure precision?

A: These bolts and nuts are CNC machined, enabling precision engineering to a tight tolerance of 0.02 mm. This process ensures each fastener is dimensionally accurate and consistent, meeting strict ISO 898 and DIN standards for quality and reliability.Q: What are the primary uses of these high tensile bolts and nuts?

A: They are intended for industrial, structural, and heavy-duty fastening purposes, including applications in automotive, construction, engineering, and machinery. The bolts provide strong, secure connections in environments demanding high strength and load-bearing capacity.Q: When should I choose different grades such as 8.8, 10.9, or 12.9 for my project?

A: Selecting the grade depends on your project's strength requirements. Grade 8.8 suits general structural use, while grades 10.9 and 12.9 are better for critical, high-stress applications demanding increased tensile strength and hardness.Q: Where are these bolts and nuts typically installed?

A: They are commonly used in settings requiring durable fastening solutions, such as building frameworks, heavy machinery assembly, bridges, and automotive components. Installation is performed using standard wrenches or spanners on the hexagonal head design.Q: What are the benefits of the various surface treatments and finishes available?

A: Surface finishes such as black oxide, zinc plating, and hot dip galvanizing enhance corrosion and rust resistance. This prolongs the bolt's lifespan, reduces maintenance, and ensures performance in harsh or outdoor environments.Q: How are these high tensile fasteners packed and supplied?

A: Depending on requirements, bolts and nuts are packed in carton boxes, gunny bags, or plastic bags. This ensures safe transportation and convenient handling for bulk orders, with a minimum order quantity of 1000 pieces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS