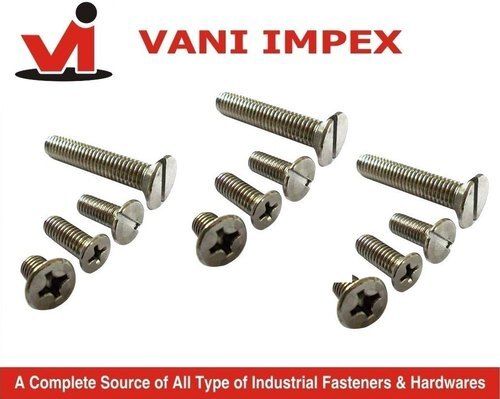

Stainless Steel Machine Screws

Product Details:

- Grade A2-70 / A4-80

- Capacity Varies by size

- Finish Bright / Matte

- Thread Type Metric, ISO

- Feature Rust resistant, durable

- Head Type Slotted / Phillips / Pan Head

- Hardness 160-220 HV

- Click to View more

Stainless Steel Machine Screws Product Specifications

- Cylindrical

- 0.05 mm

- Yes

- Rust resistant, durable

- Metric, ISO

- 160-220 HV

- Slotted / Phillips / Pan Head

- A2-70 / A4-80

- Stainless Steel

- Varies by size

- Bright / Matte

- Machine Screw

- Passivated / Self-finished

- M2 to M12

- DIN 84 / DIN 963 / ISO 7045

- Up to 960N (varies with size)

- 500-800 MPa

- General engineering, machinery, electronics, fixtures

- Slotted or Phillips

- 0.5 mm to 8 mm (Head)

- 0.25-12 Nm

Product Description

Stainless Steel Machine Screws

|

Material |

Stainless Steel |

|

Brand |

IMPORTED |

|

Head Style |

ALL TYPE OF SCREWS |

|

Usage/Application |

VARIOUS |

|

Packaging Type |

BOXES |

|

Grade |

SS 304 |

|

Quantity Per Pack |

DEPEND ON SIZE |

We are engaged in manufacturing Machine Screws. Our range of screws includes Slotted and Phillips Head Screws used in fixing or fitting various products.The basic purpose of a screw is for holding all sorts of things together, which include wood, plastic and metal. These are offered at market leading prices to our clients.

Machine Screws are in immense demand in the market for the construction of Food processing machinery, Beverage machinery, Pharmaceutical machinery and Electrical appliances. These are available in size: M3 to M6,Material Grades of SS 304.

Availability:

Slotted CSK Screw as per DIN 963

Slotted Cheese Head Screw as per DIN 84

Slotted Pan Head Screws as per DIN 85

Phillips Pan Head Screw as per DIN 7985

Phillips CSK Head Screw as per DIN 965

Features:

Bright Finishing

Genuine Grade

Good Aesthetics Look

Without Burr

Accurate Cross Recesses

Easy Tightening

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: BOXES

Reliable Performance Across Diverse Environments

Expertly manufactured to withstand both indoor and outdoor environments, our stainless steel machine screws are ideal for machinery, electronics, and general engineering applications. With a wide temperature range from -50C to +300C and superior corrosion resistance, these screws maintain structural integrity and visual appeal even in demanding conditions.

Precision Engineering and Quality Assurance

Crafted to meet DIN 84, DIN 963, and ISO 7045 standards, each machine screw features precise tolerances (0.05 mm) and robust tensile strength (500-800 MPa). Available in both pan head and slotted or Phillips drive types, these screws are rigorously passivated for optimum surface protection and feature sturdy, rust-resistant finishes.

FAQ's of Stainless Steel Machine Screws:

Q: How can I use these stainless steel machine screws in both indoor and outdoor applications?

A: These screws are made from high-grade stainless steel (A2-70 and A4-80), offering excellent corrosion and rust resistance. This makes them suitable for both indoor installations, such as electronics and fixtures, and outdoor environments exposed to weather.Q: What are the benefits of choosing A2 or A4 grade stainless steel machine screws?

A: A2-70 grade screws are non-magnetic and provide solid corrosion resistance for general applications, while A4-80 grade screws offer slightly higher corrosion resistance and are slightly magnetic, making them ideal for more demanding or marine environments.Q: When should I use coarse thread versus fine thread machine screws?

A: Coarse threads are preferred for quick assembly and when working with softer materials or components requiring greater tolerance for thread wear. Fine threads are ideal for precision assemblies, providing stronger holding power especially in hard materials.Q: Where are these machine screws commonly applied?

A: These machine screws are widely used in general engineering, machinery, electronics, and fixture installations. Their versatile design and wide size range make them suitable for manufacturing, industrial maintenance, and assembly lines.Q: What is the process for ordering and receiving these machine screws?

A: Simply select the required size, thread pitch, head type, and packaging preference (box or bulk). The minimum order quantity is 1000 pieces, making them ideal for distributors, exporters, manufacturers, suppliers, and traders across India.Q: How does the passivated surface treatment benefit the screws?

A: Passivation enhances the screw's resistance to rust and environmental wear by creating a protective oxide layer on the stainless steel surface. This extends the product's durability and ensures a clean, bright or matte finish.Q: What is the load and torque capability of these screws?

A: Depending on size and grade, the tested load capacity is up to 960N, and the recommended torque ranges from 0.25 Nm to 12 Nm, ensuring reliable fastening in most engineering and industrial uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free