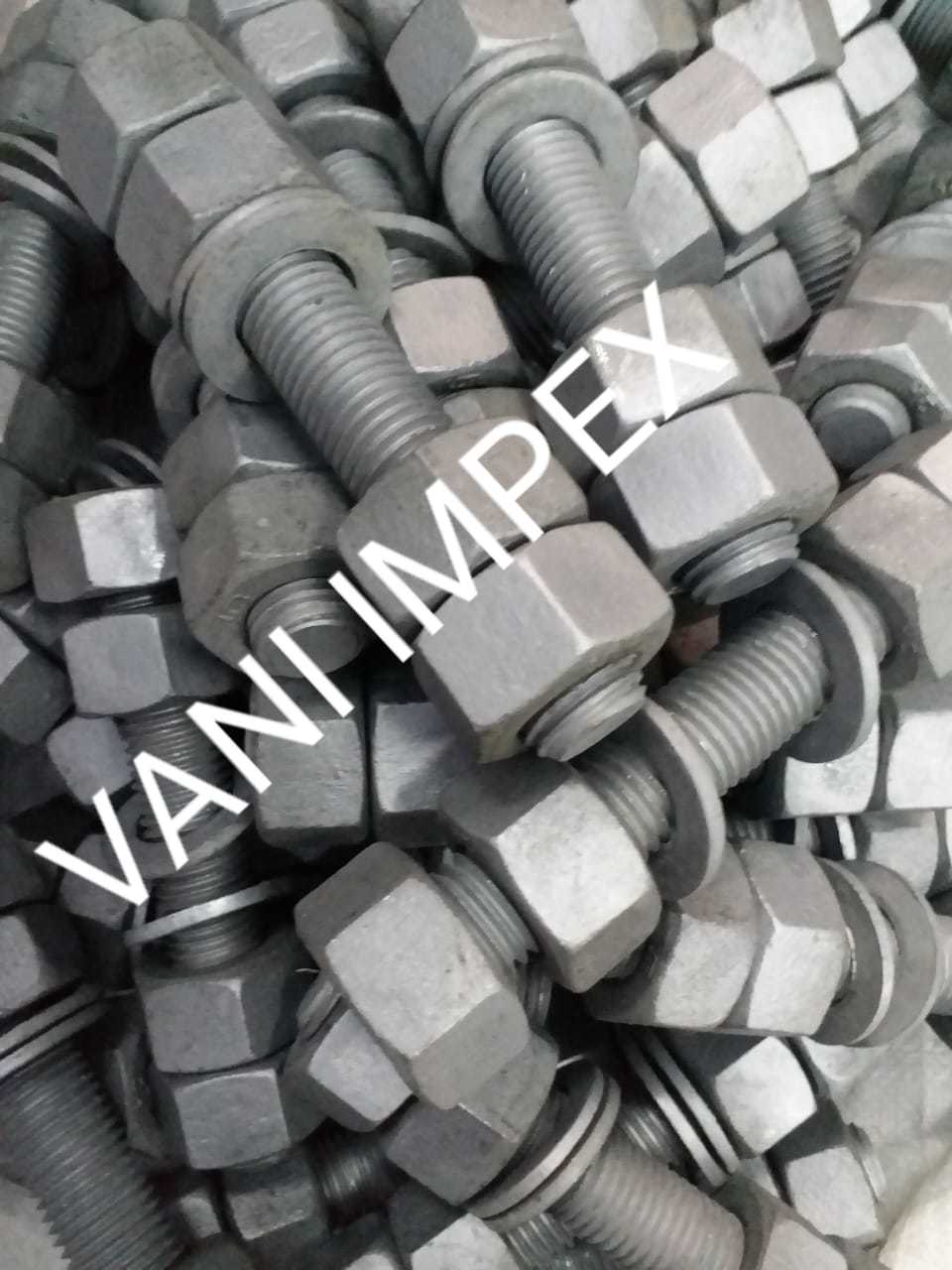

B7 Studs With 2H Heavy Hex Nuts

Product Details:

- Finish Plain, Zinc Plated, Hot Dip Galvanized, PTFE, Black

- Corrosion Resistant Yes, with suitable coating

- Feature High Strength, Durable, Precise Threads, Heat Resistant

- Grade B7

- Shape Cylindrical (studs); Hexagonal (nut)

- Diameter M6 to M48 (1/4 to 2) nominal

- Drive Type Requires wrench for installation (nut driven)

- Click to View more

X

B7 Studs With 2H Heavy Hex Nuts Price And Quantity

- 500+ Hours (With Special Coating)

- Available for Size, Length, and Coating

- Full Thread or As Required

- Grade/Heat No. on both Stud & Nut

- Negotiable

- Wooden Boxes, Gunny Bags, or As Required

- Standard as per ASTM A194 2H Spec

- Up to 450°C (Stud), as per application

B7 Studs With 2H Heavy Hex Nuts Product Specifications

- Yes, with suitable coating

- Designed for critical applications (Refer to ASTM A193 Table 4)

- Plain, Zinc Plated, Hot Dip Galvanized, PTFE, Black

- 125 ksi (minimum)

- B7

- 0.01 mm

- As per diameter / standard

- Cylindrical (studs); Hexagonal (nut)

- Unified National Coarse (UNC), Metric, BSW

- Petrochemical, Oil and Gas, Pipelines, Power Plants, Construction, Heavy Engineering

- High Strength, Durable, Precise Threads, Heat Resistant

- Stud Bolt with 2H Heavy Hex Nut

- Self, Black, HDG, PTFE, Zinc, Plain or as required

- Alloy Steel

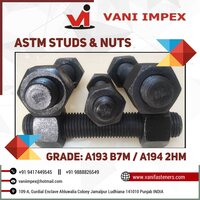

- ASTM A193 / ASTM A194

- Rockwell C35 max (studs) 248-352 HB (nuts)

- Requires wrench for installation (nut driven)

- M6 to M48 (1/4 to 2) nominal

- High tensile load-bearing

- As per application size; typically 50980 Nm

- Stud (No Head), with Heavy Hex Nut

- 500+ Hours (With Special Coating)

- Available for Size, Length, and Coating

- Full Thread or As Required

- Grade/Heat No. on both Stud & Nut

- Negotiable

- Wooden Boxes, Gunny Bags, or As Required

- Standard as per ASTM A194 2H Spec

- Up to 450°C (Stud), as per application

Product Description

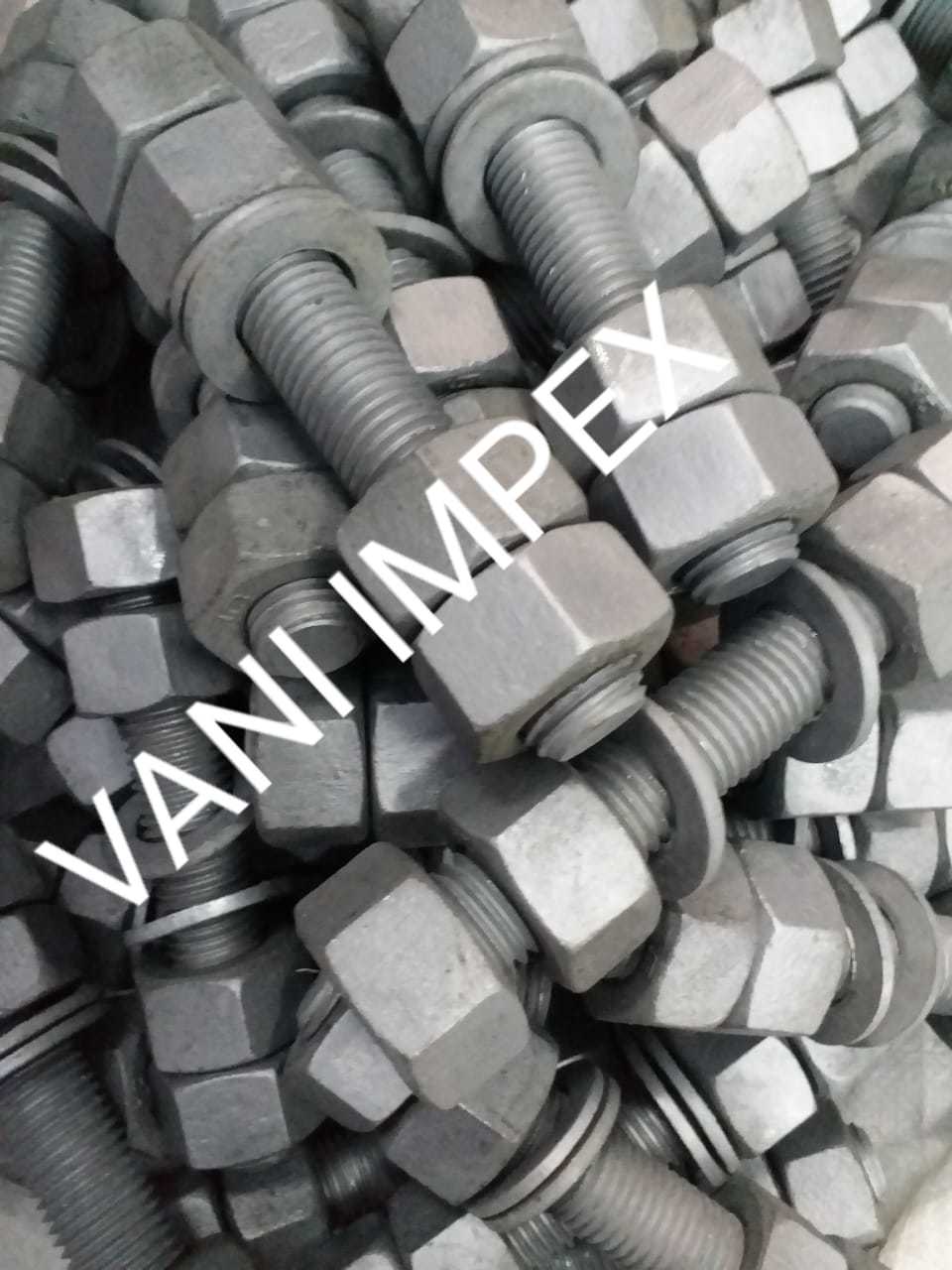

B7 Studs With 2H Heavy Hex Nuts

| Usage/Application | Industrial |

| Standard | ASTM A193 GRADE B7 STUDS, ASTM A194 2H NUTS |

| Product Type | Stud Bolts and Heavy Hex Nuts |

| Size | M 12 to M 100 Dia, 50mm to 1000mm Length, 1/2" to 4" Dia, 2" to 40" Length |

| Material | Carbon Steel |

| Grade | B7/2H |

| Surface Treatment | HDG, Zinc, Plain, Black, Black Oxide |

| Packaging Type | Boxes, Bags |

| Diameter | M 12 to M 100 |

| Threads | UNC |

| Coating | Black, Zinc, HDG |

| I Deal In | New Only |

B7 STUDS & 2H HEAVY HEX NUTS

STANDARD: ASTM A193/ASTM A194

GRADE: B7/2H

SIZE: DIA M 12 TO M 100,LENGTH 50MM TO 1000 MM,DIA 1/2" TO 2",LENGTH 2" TO 40"

FINISH: SELF, BLACK, ZINC, HDG, CADMIUM

Additional Information:

Production Capacity: 25000

Delivery Time: 15 - 30 DAYS

Packaging Details: BAGS/BOXES

Engineered for Stringent Performance

Each B7 stud and 2H heavy hex nut assembly offers excellent load-bearing capacity, precision threads, and stable performance under high temperatures. Coupled with durable surface treatments and tight tolerances, this fastener set guarantees strength and safety in critical environments.

Custom Options and Flexible Packaging

Whether you require special coating for salt spray resistance or specific thread type, these studs and nuts can be tailored for length, coating, and packaging. Options like wooden boxes or gunny bags ensure safe transit, and your specification needs can be met with minimal order quantity flexibility.

Versatility Across Applications

Adaptable for petrochemical plants, oil and gas pipelines, power stations, and construction projects, these fasteners support critical workloads. Their corrosion resistance and temperature tolerance mean they perform reliably even under harsh operating conditions.

FAQs of B7 Studs With 2H Heavy Hex Nuts:

Q: How are B7 Studs with 2H Heavy Hex Nuts used in industrial applications?

A: B7 Studs with 2H Heavy Hex Nuts are commonly used for flange connections and high-tensile bolting in pipelines, pressure vessels, and heavy equipment within petrochemical, oil and gas, and power plant industries due to their durability and heat resistance up to 450C.Q: What customization options are available for B7 Studs and 2H Nuts?

A: Sizes (diameter and length), coatings (HDG, zinc, PTFE, black), thread types (metric, UNC, BSW), and packaging (wooden boxes, gunny bags) can be customized as per client requirements. Special coatings for salt spray resistance and specific marking options are also available.Q: When should a salt spray test be requested for these fasteners?

A: Request a salt spray test for applications requiring enhanced corrosion resistance, such as marine or chemical environments. With special coatings, these studs and nuts can withstand over 500 hours in salt spray conditions as per industry standards.Q: Where are grade and heat numbers marked on the studs and nuts?

A: Grade and heat numbers are permanently marked on both the stud and the nut to ensure traceability and verification, meeting ASTM specification standards for quality assurance.Q: What is the installation process for these fasteners?

A: Installation involves threading the stud into the assembly and using a wrench to tighten the heavy hex nut to the specified torque (typically 50980 Nm, depending on size). This ensures a secure, high-tensile connection.Q: What are the benefits of using B7 Studs with 2H Heavy Hex Nuts?

A: They provide high tensile strength, precise threading, excellent heat resistance, superior durability, and corrosion protection with suitable coatings. Their compliance with ASTM standards makes them ideal for critical, high-load applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS