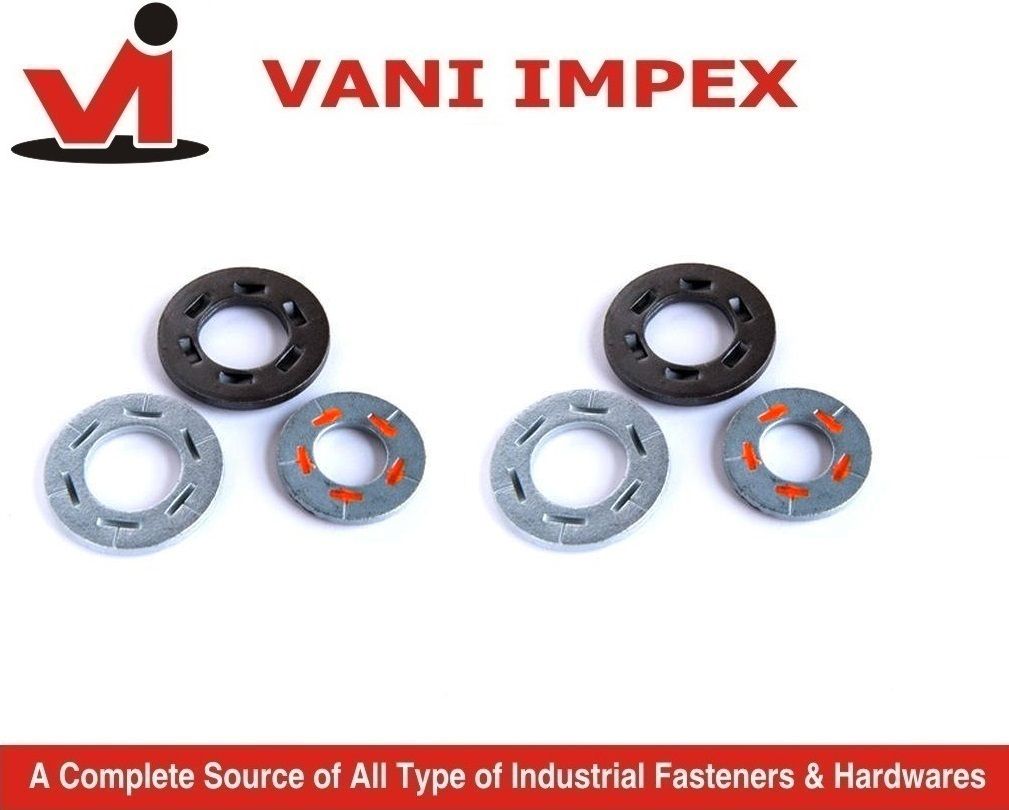

Dti Washer and Structural Washer

Product Details:

- Torque As per bolt specification

- Standard ASTM F959, EN14399, IS:6649

- Grade 8.8, 10.9, 12.9

- Thickness 3 mm - 12 mm

- Surface Treatment Hot Dip Galvanized, Zinc Plated, Self-Colored

- Finish Smooth

- Shape Round, Flat

- Click to View more

Dti Washer and Structural Washer Price And Quantity

- 1000 KG Kilograms

- 110 INR/Kilograms

Dti Washer and Structural Washer Product Specifications

- ASTM F959, EN14399, IS:6649

- Non-threaded

- As per bolt specification

- Yes

- Washer

- Hot Dip Galvanized, Zinc Plated, Self-Colored

- Structural Grade

- Round

- 3 mm - 12 mm

- 8.8, 10.9, 12.9

- Structural Bolting, Preload Indication, Steel Construction

- Smooth

- Up to 400 kN

- Direct Tension Indication, High Load Bearing

- 16 mm - 36 mm

- DTI Washer, Structural Washer

- Round, Flat

- 800 - 1200 MPa

- 0.10 mm

- High Strength Alloy Steel

- HB 250 - 350

Dti Washer and Structural Washer Trade Information

- All India

Product Description

Dti Washer, Structural Washer

DTI Washers - Direct Tension Indicator Washer - ASTM F959

DTI Washer is the worlds simplest cost effective solution to control the tensioning of bolts. These unique, patented fasteners deliver consistent, reliable bolt tension, along with installation and inspection efficiency. They are used every day to achieve required tension loads on bolts in countless applications including: structural steel buildings and bridges, studs used in the petro-chemical industry, anchor bolts and SAE cap screws for automotive applications. This washer is also known as ASTM F959 Washer.

Available from: M16 TO M36

Special sizes available as per customer requirements.

High Strength & Precision Engineering

Crafted using forging and heat treatment, these washers deliver consistent hardness (HB 250-350) and exceptional load-bearing capacity up to 400 kN. The 0.10 mm tolerance and smooth finish ensure secure fitting and faultless performance in critical structural joints.

Direct Tension Indication Advantage

Featuring indented markings for tension indication, these washers simplify preload verification, minimizing installation errors and optimizing bolt fastening. This results in safer and more efficient steel constructions while reducing inspection time.

Versatile Application & Long-Term Durability

Compatible with Grade 8.8, 10.9, and 12.9 bolts, suitable for round and flat washer applications in steel construction projects. Designed for both indoor and outdoor use, they are corrosion resistant, RoHS compliant, and maintain performance in extreme temperatures (-20C to +300C).

FAQ's of Dti Washer and Structural Washer:

Q: How do DTI and Structural Washers provide direct tension indication?

A: DTI (Direct Tension Indicating) washers have specially indented markings that compress as the bolt is tightened. This compression visually or physically indicates the bolt tension, helping installers verify that the correct preload has been achieved during structural assembly.Q: What environments are these washers suitable for?

A: These washers are engineered for both indoor and outdoor environments, thanks to their high strength alloy steel construction and corrosion-resistant surface treatments such as hot dip galvanizing and zinc plating. They can withstand temperatures from -20C to +300C.Q: When should I use a DTI washer versus a standard washer?

A: Use DTI washers when direct monitoring of bolt tension is crucial, particularly in structural bolting and steel construction applications. They offer preload indication and higher safety assurance. Structural washers are preferred for distributing load and minimizing surface damage under high-tension fasteners.Q: Where are these washers typically installed within a structure?

A: These washers are primarily used in steel connections-such as beams and columns-where precise bolt tension and secure load distribution are vital. They are installed under the bolt head or nut as part of standard bolt fastening methods.Q: What is the process for installing these washers?

A: Installation follows standard bolt fastening procedures. Position the washer under the fastener, tighten the bolt until the indented markings are compressed to the specified tension, confirming preload has been correctly set as per bolt specification.Q: What are the main benefits of choosing these washers for my project?

A: Benefits include precise preload verification, high-load bearing capacity (up to 400 kN), long service life (25+ years), RoHS compliance, and exceptional corrosion resistance. This ensures reliable structural integrity and simplifies inspection.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS