Galvanized CSK Allen Screw

8 INR/Piece

Product Details:

- Shape Flat Head

- Hardness 28-32 HRC

- Thread Type Metric (ISO) Thread

- Load Capacity Up to 980 N (varies by size)

- Corrosion Resistant Yes

- Torque 2.5 Nm - 80 Nm (size dependent)

- Surface Treatment Galvanized

- Click to View more

X

Galvanized CSK Allen Screw Price And Quantity

- 8 INR/Piece

- 25000 Piece

- RoHS Compliant

- Yes

- Standard metric pitch

- Yes (material dependent)

- 6 mm to 100 mm

- Silver Grey

- Case Hardened

- Allen Key / Hex Wrench

- Box/Packet

- 100 Pieces

Galvanized CSK Allen Screw Product Specifications

- DIN 7991 / ISO 10642

- Zinc Plated

- A2-70 / A4-70

- 0.05 mm

- Min 700 MPa

- Allen Screw

- Yes

- 2.5 Nm - 80 Nm (size dependent)

- As per diameter and length selected

- Galvanized

- 28-32 HRC

- Metric (ISO) Thread

- Countersunk (CSK)

- Up to 980 N (varies by size)

- Industrial Machinery, Furniture, Automotive Assemblies

- Rust Resistant, High Strength

- Up to 1000 kg/f (varies by size)

- M3 to M16

- Carbon Steel

- Hex Socket (Allen)

- Flat Head

- RoHS Compliant

- Yes

- Standard metric pitch

- Yes (material dependent)

- 6 mm to 100 mm

- Silver Grey

- Case Hardened

- Allen Key / Hex Wrench

- Box/Packet

- 100 Pieces

Product Description

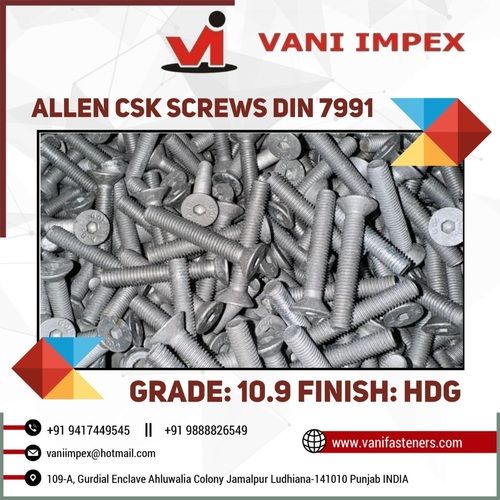

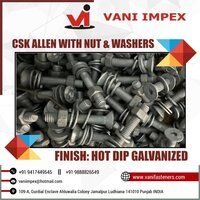

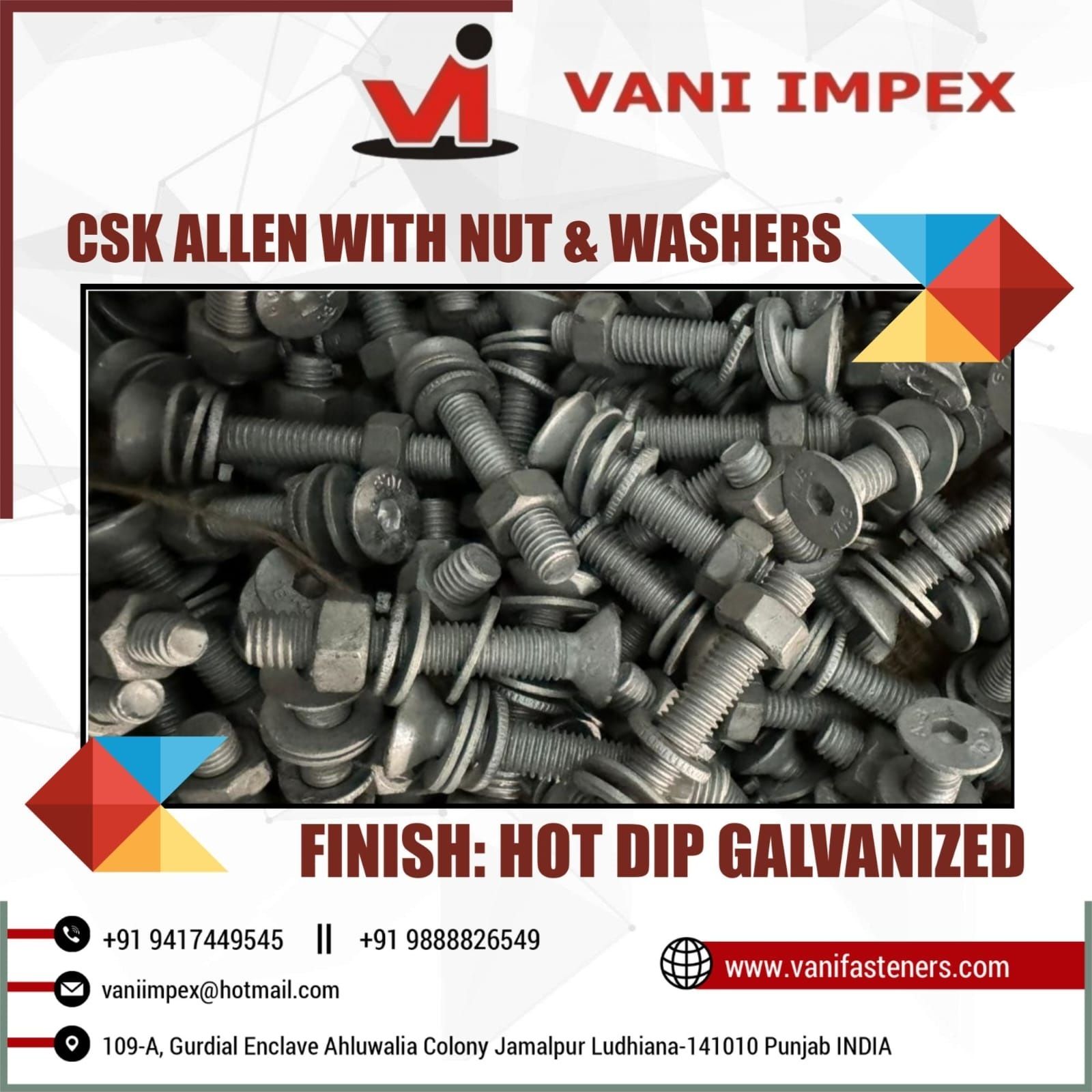

STANDARD : DIN 7991GRADE : 10.9

METRIC SERIES

DIA : M 2 - M 24

LENGTH - 3MM - 120MM

INCH SERIES BSW

DIA - 1/4" - 3/4"

LENGTH - 3/8" - 4"

Additional Information:

- Production Capacity: 100000 PCS

- Delivery Time: 2 - 4 WEEKS

- Packaging Details: BAGS/BOXES

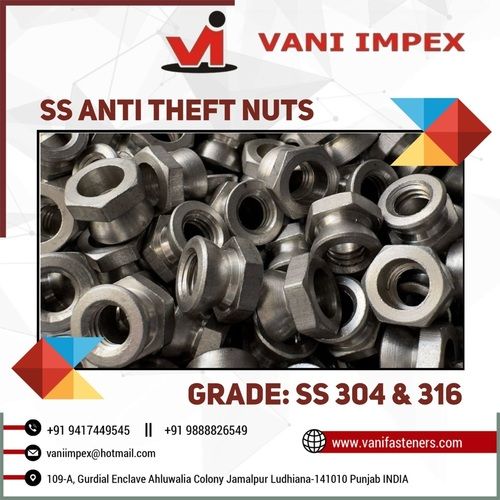

Superior Strength and Durability

Engineered with a minimum tensile strength of 700 MPa and hardness between 28-32 HRC, these CSK Allen screws are ideal for high-stress environments. The galvanized, zinc-plated finish enhances corrosion resistance, extending the lifespan of fastenings in demanding industrial or outdoor applications.

Precision Engineering for Diverse Needs

Available in a wide diameter range from M3 to M16 and lengths spanning 6 mm to 100 mm, each fastener maintains stringent tolerances of 0.05 mm. Adherence to DIN 7991 / ISO 10642 ensures consistent compatibility and maximum reliability across machinery, furniture, and automotive assemblies.

Safe and Efficient Installation

Installation is straightforward using a hex socket (Allen key or hex wrench), providing a secure fit and flush surface finish. The case-hardened carbon steel and standard metric pitch thread enable reusability, making these screws both economical and dependable for repeated assembly and disassembly.

FAQ's of Galvanized CSK Allen Screw:

Q: How should the Galvanized CSK Allen Screw be installed for optimal performance?

A: For best results, use an appropriately sized Allen key or hex wrench to drive the screw into the pre-threaded hole. Ensure the countersunk head sits flush with the surface, which provides a secure and streamlined finish.Q: What are the main benefits of choosing these screws for automotive or machinery assemblies?

A: These screws deliver high strength (minimum 700 MPa) and corrosion resistance due to their galvanized zinc-plated finish. The precise manufacturing ensures a tight fit, enhancing the reliability and longevity of assembled components.Q: When is it recommended to use a case-hardened, RoHS-compliant Allen screw?

A: Use these screws in applications requiring high durability, environmental compliance, and rust resistance, such as industrial machinery, furniture, and automotive assemblies, especially where part reusability and precision are essential.Q: Where are these screws commonly used?

A: They are extensively used in industries like automotive manufacturing, machinery assembly, and high-quality furniture construction, thanks to their strength, compatibility, and corrosion resistance.Q: What is the process for selecting the correct screw size and diameter?

A: Consider the mechanical load, the required thickness, and the diameter of the mounting hole. Choose from M3 to M16 diameter and 6 mm to 100 mm length to match your assembly needs, ensuring the load and torque capacities are met.Q: Can these screws be reused after initial installation?

A: Yes, thanks to their case-hardened design and robust material, these screws are suitable for repeated assembly and disassembly without compromising performance, provided installation methods are properly followed.Q: Are these screws resistant to magnetic fields and rust, and what is their environmental compliance status?

A: Depending on the carbon steel grade, they can be magnetic. The galvanized zinc finish provides strong rust resistance, and the screws are RoHS compliant to support environmental and safety standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS