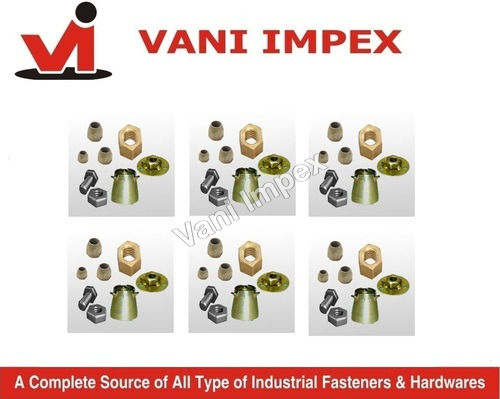

Hdg Plated Wedge Anchor Fasteners

Product Details:

- Finish HDG Plated

- Hardness 35-45 HRC

- Feature Expansion Type, Easy Installation

- Corrosion Resistant Yes (Hot Dip Galvanized)

- Surface Treatment HDG (Hot Dip Galvanized) Plated

- Grade 4.6 / 5.8 / 8.8

- Load Capacity Up to 3,000 kg

- Click to View more

Hdg Plated Wedge Anchor Fasteners Price And Quantity

Hdg Plated Wedge Anchor Fasteners Product Specifications

- Metric Threaded

- Wedge Anchor

- Up to 3,000 kg

- Varies by Diameter (8mm-20mm)

- M8 to M20

- Cylindrical

- 4.6 / 5.8 / 8.8

- 0.2 mm

- High Load Bearing

- Hex Head

- Yes (Hot Dip Galvanized)

- Expansion Type, Easy Installation

- Concrete Anchoring, Structural Fixings

- DIN, ASTM, ISO

- 35-45 HRC

- HDG Plated

- Hex

- Carbon Steel

- 600-860 MPa

- Recommended 40-120 Nm

- HDG (Hot Dip Galvanized) Plated

Product Description

Hdg Plated Wedge Anchor Fasteners|

Size |

M 8 x 75 to M 24 x 300 |

|

Material |

M 8 x 75 to M 24 x 300 |

|

Packaging Type |

Bags |

|

Surface Finishing |

HDG |

|

Brand |

VANI |

|

Country of Origin |

Made in India |

HDG Plated Wedge Anchor Fasteners

HDG Plated Wedge Anchor Fasteners are broadly used in mechanical and electrical fields. This multipurpose anchor can also be used for hollow as well as solid concrete works. These are made by using the top quality stainless steel, under the directions of the best manufacturers of the market. These are acknowledged for their quality,strength, finishing, durability, corrosion resistance and easy installation.Furthermore, these HDG Plated Wedge Anchor Fasteners can be availed from us at industry leading prices.

Additional Information:

Production Capacity: 50000 PCS MONTHLY

Delivery Time: 7 DAYS

Packaging Details: BOXES

Engineered for Secure and Lasting Fixation

Designed with a uniform radial expansion system, these wedge anchor fasteners achieve a firm, vibration-resistant hold in both concrete and dense masonry. The HDG coating guards against corrosion in challenging environments, while the precision tolerance (0.2 mm) ensures consistent performance across structural and general-purpose anchoring tasks.

Versatile Sizing and Adaptability

Available from 40 mm to 200 mm in length and M8 to M20 in diameter, these anchors accommodate a diverse range of applications and load requirements. Backed by high load-bearing capacity and metric threading, installation is straightforward using a simple drill-and-expand process suitable for rapid deployment.

Certified Quality for Demanding Projects

Each fastener adheres to international DIN, ASTM, and ISO standards, ensuring reliability and safety. Featuring a hardness between 35-45 HRC and tensile strength up to 860 MPa, these anchors are trusted by distributors, exporters, manufacturers, suppliers, and traders across India for both commercial and structural fixings.

FAQs of Hdg Plated Wedge Anchor Fasteners:

Q: How are HDG Plated Wedge Anchor Fasteners installed in concrete or masonry?

A: To install the anchor, drill a hole in the concrete or dense masonry to the recommended diameter and depth, insert the wedge anchor, and tighten the hex head. The expansion mechanism will then secure the anchor with a uniform radial grip for stable fixing.Q: What types of environments are these fasteners suitable for?

A: These anchors are designed to perform reliably in concrete and dense masonry, across environments exposed to moisture, chemicals, or varying temperatures (from -20C to +150C). The HDG (Hot Dip Galvanized) finish delivers exceptional rust and corrosion resistance.Q: When should I choose HDG Plated Wedge Anchor Fasteners over other types?

A: Select these fasteners when high load-bearing, superior corrosion resistance, and compliance with ISO 9001 or EN standards are required. They are especially suited for structural applications and areas with challenging environmental conditions.Q: Where can I source these wedge anchors in India?

A: These fasteners are widely available through various distributors, exporters, manufacturers, suppliers, and traders across India, either in boxed sets or bulk packaging, depending on your project needs.Q: What is the process behind the uniform radial expansion mechanism?

A: Once the anchor is inserted and the hex head tightened, the expansion sleeve uniformly expands outward against the hole walls. This creates a strong, stable grip that ensures the anchor remains secure under both static and dynamic loads.Q: What are the primary benefits of using these anchors for concrete anchoring?

A: Key benefits include quick and easy installation, strong holding power due to uniform radial expansion, excellent rust and corrosion resistance via HDG finish, and certified reliability for high-load applications in Indias diverse construction sector.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free