Hot Dip Galvanized Fasteners For Solar Power Plants

Product Details:

- Surface Treatment Hot Dip Galvanized

- Thickness 5 mm to 30 mm

- Drive Type Hex, Slotted, Phillips

- Capacity Heavy Duty Applications

- Thread Type Metric, UNC

- Standard IS, DIN, ISO, ASTM

- Shape Round, Hexagonal, Square

- Click to View more

X

Hot Dip Galvanized Fasteners For Solar Power Plants Product Specifications

- Hot Dip Galvanized

- 4.6, 8.8, 10.9, 12.9

- 5 mm to 30 mm

- Galvanized

- Hex, Slotted, Phillips

- Mild Steel, High Tensile Steel

- Rust Resistant, Weather Proof, Durable

- M6 to M20

- Heavy Duty Applications

- +/- 0.02 mm

- Upto 550 Nm

- Metric, UNC

- IS, DIN, ISO, ASTM

- Hex, Flat, Round, Countersunk

- 400-1200 MPa

- Round, Hexagonal, Square

- Yes

- Varies by size - up to 60 kN

- Up to 38 HRC

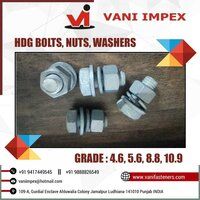

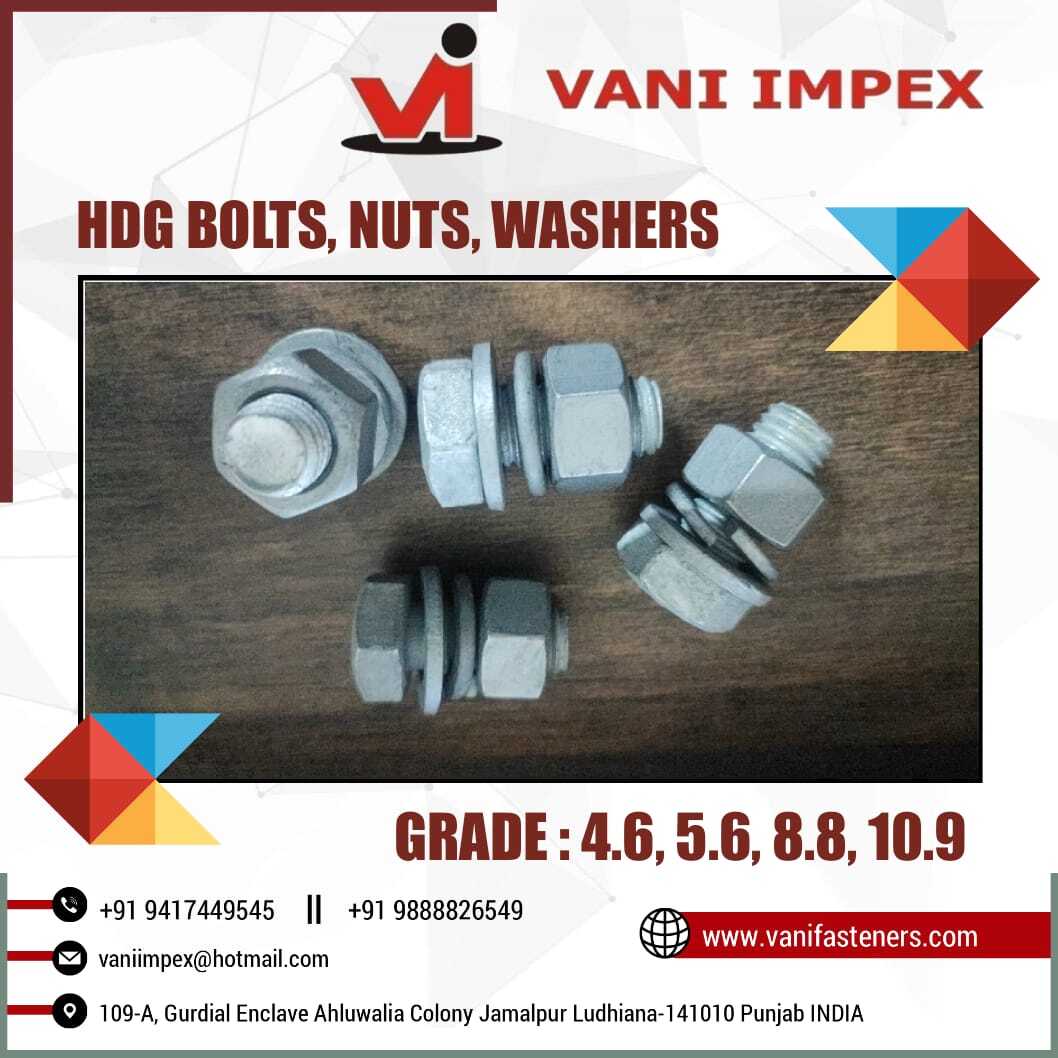

- Bolts, Nuts, Washers, Screws

- Solar Power Plants, Photovoltaic Mounting Structures

- 25 mm to 200 mm

- -20C to +60C

- Yes

- Fine & Coarse as per Norms

- Manual or Power Tool

- Silver / Grey

- 70 Microns

- Gunny Bags / Carton Boxes

Product Description

Hot Dip Galvanized Fasteners For Solar Power Plants

| Material | MS, HIGH TENSILE |

| Size | M 6 TO M 48 |

| Brand | VANI |

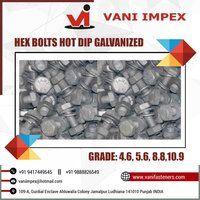

| Grade | 4.6, 5.6, 8.8, 10.9 |

| Type | Fastener |

| Quantity Per Pack | 50 KGS |

| Coating | HOT DIP GALVANIZED |

| Surface Finish | HOT DIP GALVANIZED |

| Packaging Type | GUNNY BAGS/BOXES |

| Country of Origin | Made in India |

We are passionately engaged in supplying an exclusive assortment of Hot Dip Galvanized Fasteners. Our offered assortment is precisely manufactured at vendors end using optimum-grade raw material and advanced machining process in compliance with set industrial norms. These are available in different sizes and specifications according to client-specific requirements. Apart from this, the offered range has excellent finishing & galvanized coating and is widely used for joining heavy duty components.

Features:

- Easy to install

- Excellent finish

- Resistance against corrosion

Specification:

- Dia Range : M 6 to M 100 / 1/4" TO 4"

- Length Range : 20 mm to 600 mm/ 3/4" to 24"

- Grade: 4.6, 5.6, 6.8, 8.8, 10.9, 12.9, 8.8S, 10.9S, R, S, T, V, X etc.

Additional Information:

- Delivery Time: 25 - 30 DAYS

- Packaging Details: BAGS

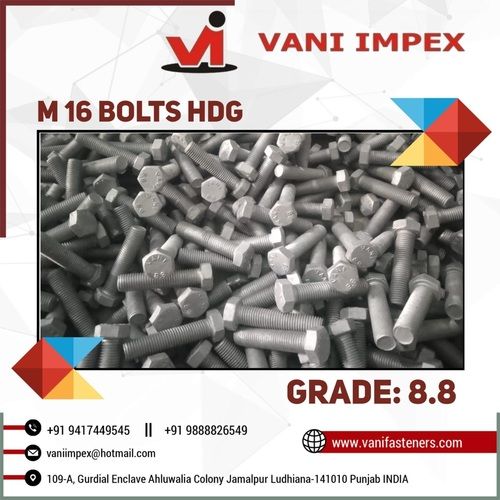

Superior Weather & Corrosion Resistance

These hot dip galvanized fasteners are specially processed for excellent resistance to rust, weather, and UV exposure. The minimum 70-micron coating thickness ensures longevity, protecting the fasteners even in harsh environments. This makes them ideal for open-field solar power plants subjected to diverse weather conditions.

Precision Engineering & Heavy Duty Capacity

Engineered to tight tolerances (+/- 0.02 mm) and available in grades from 4.6 to 12.9, these fasteners offer reliable performance in high-load scenarios. A tensile strength up to 1200 MPa and load capacity up to 60 kN provide assurance for the structural integrity of photovoltaic mounting systems.

Flexible Installation & Wide Compatibility

Supplied in various shapes and thread types, these fasteners work with manual or power-tool installation. Metric and UNC thread options, along with multiple head types (hex, flat, round, countersunk) and drive types, make them adaptable to multiple solar mounting applications.

FAQ's of Hot Dip Galvanized Fasteners For Solar Power Plants:

Q: How are hot dip galvanized fasteners beneficial for solar power plant installations?

A: Hot dip galvanized fasteners offer superior durability and resistance to rust and weather, which is crucial in outdoor solar power plant environments. The thick galvanized coating ( 70 microns) and UV resistance extend the service life of mounting structures, minimizing maintenance needs and ensuring long-term reliability.Q: What types of fasteners are included in the range for solar power plants?

A: This range includes bolts, nuts, washers, and screws in various shapes such as round, hexagonal, and square. They come with different head types (hex, flat, round, countersunk) and thread options (fine, coarse, metric, UNC), ensuring suitability for assorted photovoltaic mounting applications.Q: Where can these fasteners be used besides solar power plants?

A: While optimized for photovoltaic mounting structures in solar plants, these heavy-duty, corrosion-resistant fasteners can also be employed in other outdoor or structural projects that require robust, weatherproof connections, such as infrastructure or construction projects exposed to the elements.Q: What is the recommended process for installing these fasteners?

A: Installation can be completed using manual hand tools or power tools, depending on project needs. Choosing the appropriate torque (up to 550 Nm) and thread pitch in accordance with manufacturer guidelines ensures secure and stable connections in the mounting structures.Q: When should hot dip galvanized fasteners be selected over other types?

A: Select hot dip galvanized fasteners when projects demand high corrosion resistance, extended durability, and exposure to harsh or outdoor environments, such as solar installations. Their robust coating and rust-proof properties make them ideal for challenging conditions where longevity is a priority.Q: What standards do these fasteners comply with, and why is this important?

A: These fasteners adhere to IS, DIN, ISO, and ASTM standards. Compliance assures customers of their reliability, consistent manufacturing quality, and compatibility with global industry requirements for safety and structural integrity.Q: How does the choice of material and finish enhance the product's performance?

A: Made from mild steel or high-tensile steel and finished through hot dip galvanizing, these fasteners offer exceptional tensile strength (400-1200 MPa) and hardness (up to 38 HRC). The galvanized finish ensures resistance to corrosion and wear, reinforcing their suitability for heavy-duty and long-term solar applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free