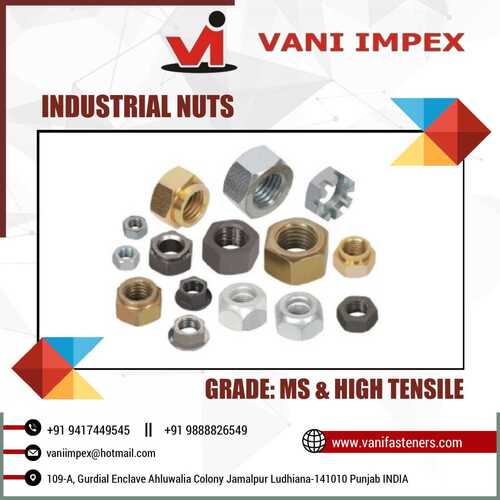

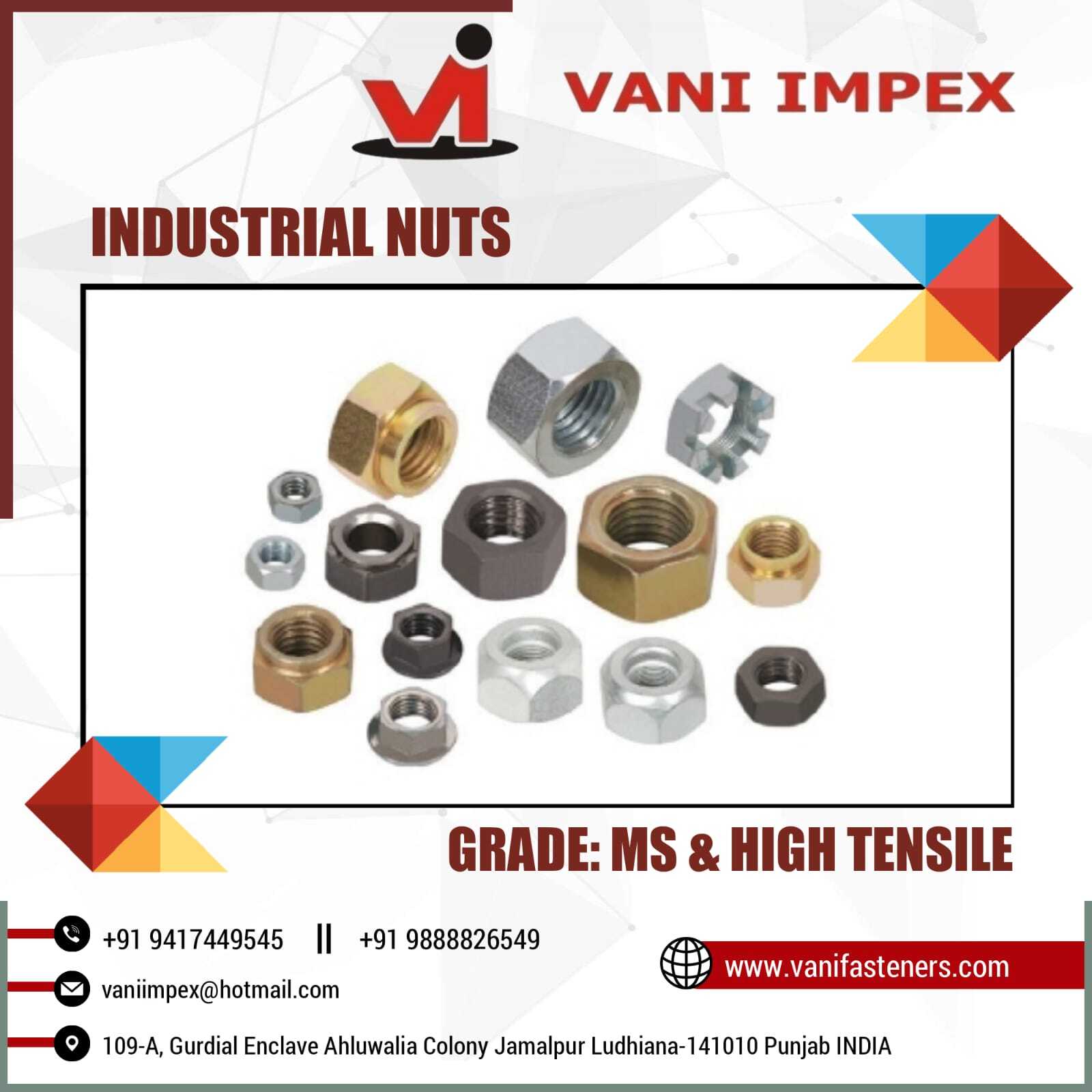

Industrial Nuts

Product Details:

- Feature High Strength, Precise Threading

- Capacity Up to 20,000 pcs/day

- Torque Up to 450 Nm

- Head Type Hexagonal

- Diameter M6 to M48

- Drive Type External Hex

- Shape Hex

- Click to View more

Industrial Nuts Price And Quantity

Industrial Nuts Product Specifications

- Hex Nut

- M6 to M48

- Hexagonal

- Zinc Plated, Hot Dip Galvanized, Black Oxide

- 0.01 mm

- Up to 450 Nm

- Yes

- Metric, UNC, UNF

- Up to 20,000 pcs/day

- High Strength, Precise Threading

- 3 mm to 30 mm

- 8.8, 10.9, 12.9

- Up to 1200 MPa

- 35-45 HRC

- DIN, ASTM, ISO, JIS

- Polished, Plain, Coated

- Industrial Machinery, Construction, Automotive

- Hex

- Up to 15 Ton

- Carbon Steel, Alloy Steel, Stainless Steel

- External Hex

Product Description

Industrial Nuts

|

Size |

M 6 TO M 36 |

|

Brand |

VI |

|

Material |

MILD STEEL, HIGH TENSILE STEEL |

|

Usage/Application |

Commercial |

|

Shape |

Hex |

|

Standard |

IS,DIN,ISO,BS |

|

Finishing |

Zinc Plated |

|

Quantity Per Pack |

50 Kg |

|

Packaging Type |

Bags/Boxes |

|

Grade |

4.6, 5.6, 8.8, 10.9 |

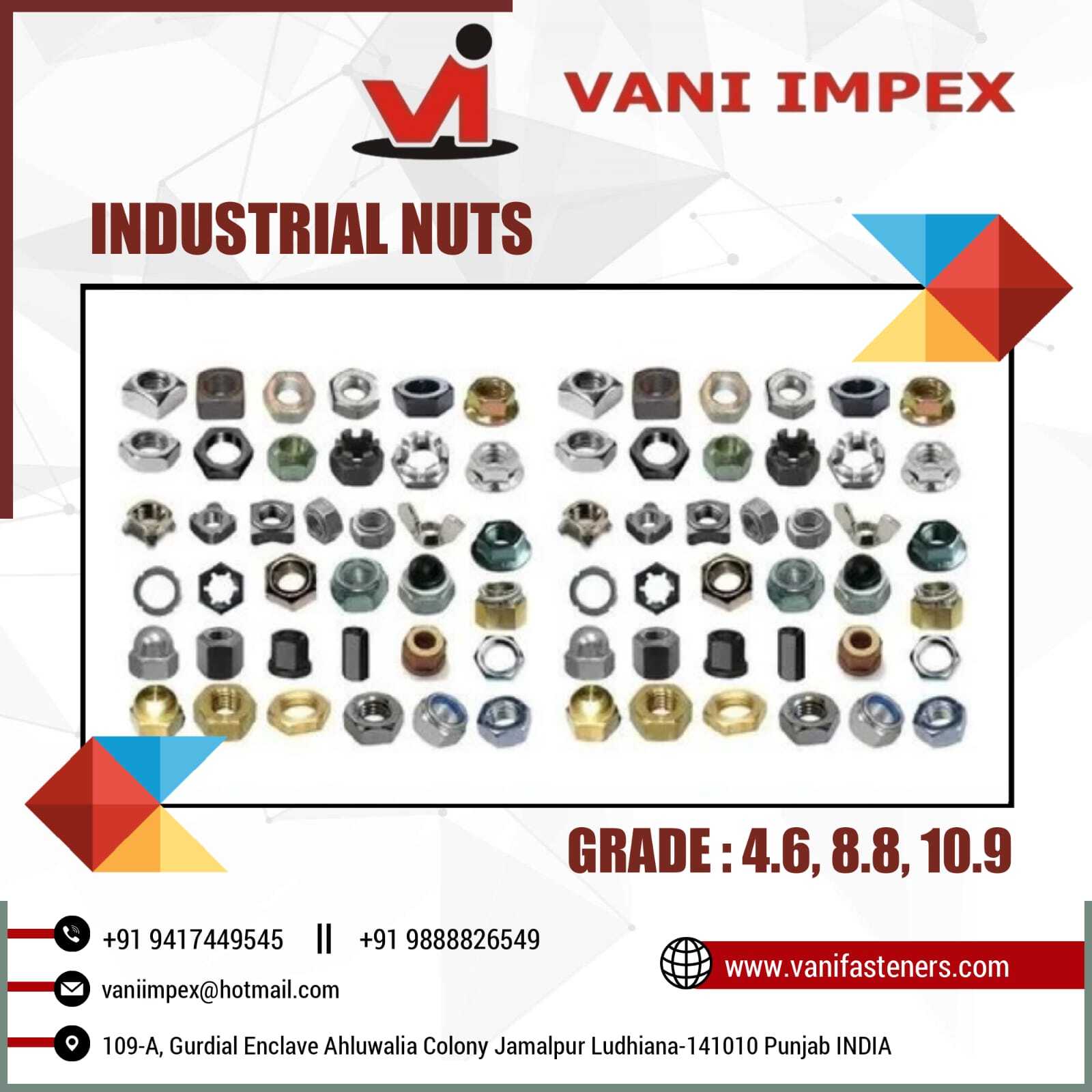

We offer various range of fastening items like Hex Nuts, Flange Nutsand others that are made of High Grade Metals. Available in standardized dimensions, the range can also be customized to suit the specific requirements of the clients.

Our range includes:

We produce various types of Hex Nuts as per following parameters

Standard : DIN-555/ISO-4034/EN-24034, BS-4190,DIN-934/ISO-4032/EN-24032, IS : 1363

Material : Carbon Steel, Boron Steel & Alloy Steel

Finishes : HDG, Zinc Plated, Self, Black

Grades : 4, 5, 6, 8, 10, 12

Additional Information:

Production Capacity: 10000 kgs

Delivery Time: 25 - 30 DAYS

Packaging Details: BOXES, BAGS

Precision Engineered for Demanding Environments

Our industrial hex nuts deliver unmatched strength, corrosion resistance, and thread precision, making them suitable for the toughest heavy-duty applications. Manufactured using high-grade materials and advanced cold forging, they excel in environments requiring robust load and torque performance. With custom sizes and a comprehensive range of finishes, these nuts are ideal for projects where reliability and compliance with global standards are critical.

Versatility Across Industries

Suitable for use in automotive, construction, and industrial machinery sectors, our nuts support applications necessitating a secure, high-strength fastening solution. They come in a variety of plating options for added corrosion protection and are tested to maintain integrity under extreme temperatures and substantial mechanical loads. Bulk packaging options are also available to meet large-scale project requirements efficiently.

FAQ's of Industrial Nuts:

Q: How are your industrial nuts manufactured to ensure high strength and durability?

A: Our nuts are produced using a cold forging process and made from premium carbon steel, alloy steel, or stainless steel. This technique, coupled with surface treatments like zinc plating or hot dip galvanization, delivers exceptional tensile strength (up to 1200 MPa) and rust-proof properties, suitable for intense industrial use.Q: What packaging options do you provide for large-scale projects?

A: We offer flexible packaging solutions, including boxes, cartons, and bulk packaging, to accommodate the varied needs of distributors, manufacturers, and project sites. Each packaging type is designed to ensure safe and efficient transport, regardless of order size.Q: When should I use these nuts over standard fasteners?

A: Choose our high-grade industrial nuts when your application demands superior load capacity (up to 15 tons), precise threading, corrosion resistance, and adherence to international standards such as DIN, ASTM, ISO, or JIS-ideal for construction, automotive, or heavy machinery sectors.Q: Where are your industrial nuts commonly used?

A: These nuts are widely utilized in industrial machinery, construction projects, and automotive assemblies where reliability under heavy load and harsh conditions is essential. Their high strength and corrosion resistance suit both indoor and outdoor installations.Q: What benefits do your nuts offer for custom applications?

A: We provide custom sizes and a selection of thread types (Metric, UNC, UNF) to meet the unique requirements of diverse projects. This flexibility ensures optimal fit, increased safety, and performance consistency in specialized applications.Q: Can you describe the quality standards and tolerances your nuts conform to?

A: Our nuts are manufactured to strict tolerances of 0.01 mm and comply with major global standards such as DIN, ASTM, ISO, and JIS. Each batch undergoes rigorous quality checks to ensure uniform hardness (35-45 HRC), precise threading, and high mechanical strength.Q: What is the typical lead time and minimum order quantity for bulk orders?

A: The minimum order quantity is 500 pieces, with a manufacturing capacity of up to 20,000 pieces per day. Lead time may vary based on customization and order volume, but our advanced production processes ensure efficient fulfillment to support project timelines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS