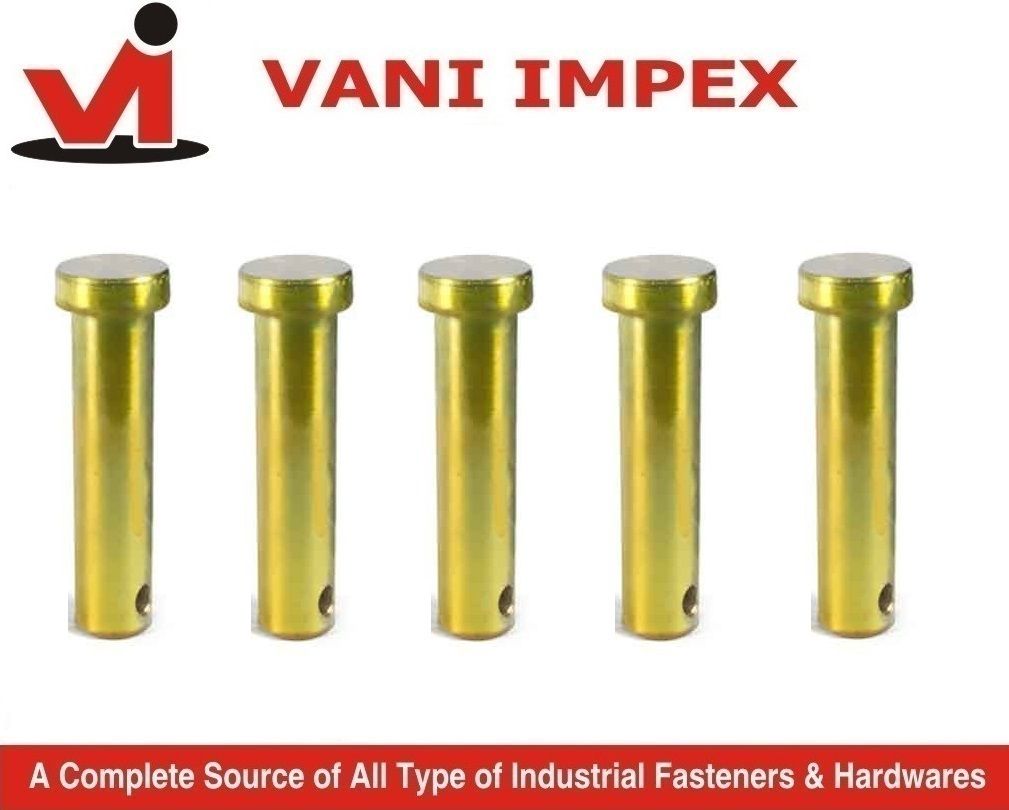

Rotavator Pin

Product Details:

- Tool Type Implement Pin

- Usage & Applications Rotavator, agricultural implements, machinery connection

- Features Corrosion resistant, sturdy design, easy to install

- Noise Level Silent operation

- Shape Cylindrical with locking collar

- Product Type Pin / Locking Pin

- General Use Connecting and securing parts of rotavator machinery

- Click to View more

X

Rotavator Pin Price And Quantity

Rotavator Pin Product Specifications

- Connecting and securing parts of rotavator machinery

- High-grade Steel / Mild Steel

- 0.08 kg approx.

- Implement Pin

- Silver/Metallic Grey

- Pin / Locking Pin

- Silent operation

- Rotavator Pin

- Standard (custom sizes available)

- Rotavator, agricultural implements, machinery connection

- Corrosion resistant, sturdy design, easy to install

- 45mm x 10mm x 10mm (approx)

- Cylindrical with locking collar

Product Description

Rotavator Pin| Brand | Universal |

| Model Name/Number | SHAKITMAN, SONALIKA AND ALL OTHER MODELS |

| Country of Origin | Made in India |

| Size | M 28 x 5", M 28 x 6", M 25 x 5" |

| Colour | Yellow, Black, Red |

| Packing | Loose, Boxes |

| Dia | 28mm, 25mm |

| Length | 5", 6" |

Rotavator Pin

Being client centric organization, we are actively engaged in offering the best quality Rotavator Pin that is mostly used with the spare parts of rotovators like pipes, yoke, and shafts. The pin offered by us is manufactured using cutting edge technology with top quality raw material in line with defined industry norms. Owing to its unique features such as accurate dimension and fine finish, our provided pin has huge demand in the market. In order to meet the divergent demands of our valued clients, we offer this pin in various sizes at market leading rates.

Features:

- Optimum strength

- Ruggedness

- High load bearing capacity

Additional Information:

- Production Capacity: 10000

- Delivery Time: 25 - 30 DAYS

- Packaging Details: BOXES

Exceptional Rust Protection

This rotavator pin utilizes a zinc-plated surface, offering long-term rust protection even in harsh field environments. The finish preserves the pins integrity and performance, reducing maintenance needs and extending operational lifespan for agricultural machinery.

Precision Engineering and High Strength

Manufactured through precision machining and heat treatment, the pin achieves superior tensile strength (up to 1200 MPa) and a hardness of 50-55 HRC. Its sturdy construction ensures reliable connections and enhanced safety during heavy agricultural tasks.

Versatile Compatibility and Simple Installation

Designed to fit most standard rotavator brands and configurations, the 20 mm diameter and grooved locking system provide versatility and secure attachment. The cylindrical shape with locking collar ensures quick, hassle-free installation and removal for seamless equipment maintenance.

FAQs of Rotavator Pin:

Q: How does the zinc-plated finish benefit the rotavator pin?

A: The zinc-plated surface finish provides enhanced corrosion resistance, protecting the pin from rust and environmental damage. This ensures a longer service life, especially when used in agricultural environments exposed to moisture and chemicals.Q: What is the typical process for installing the rotavator pin?

A: Installation involves aligning the pin with designated holes in the rotavator machinery, then securing it using a cotter or locking clip through the grooved section. This straightforward method allows for quick and secure attachment or removal.Q: When should the rotavator pin be lubricated or maintained?

A: Though the pin is designed for low maintenance, periodic lubrication is recommended to ensure smooth operation and prolong its service life. Inspect the pin regularly for wear and lubricate as needed, based on usage intensity.Q: Where can this rotavator pin be used?

A: This pin is suitable for use in most standard brand rotavators, as well as other agricultural implements and machinery that require a secure connection between moving parts. It is distributed, exported, and supplied by manufacturers and traders throughout India.Q: What are the main benefits of using a precision machined and heat treated pin?

A: Precision machining and heat treatment endow the pin with high tensile strength and optimal hardness. This results in dependable durability, resistance to deformation, and the ability to withstand rigorous agricultural operations.Q: How does the locking groove feature improve safety and ease of use?

A: The grooved section is engineered to hold a cotter or locking clip securely in place, preventing accidental disengagement during operation. This design enhances safety and streamlines the installation and removal process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS