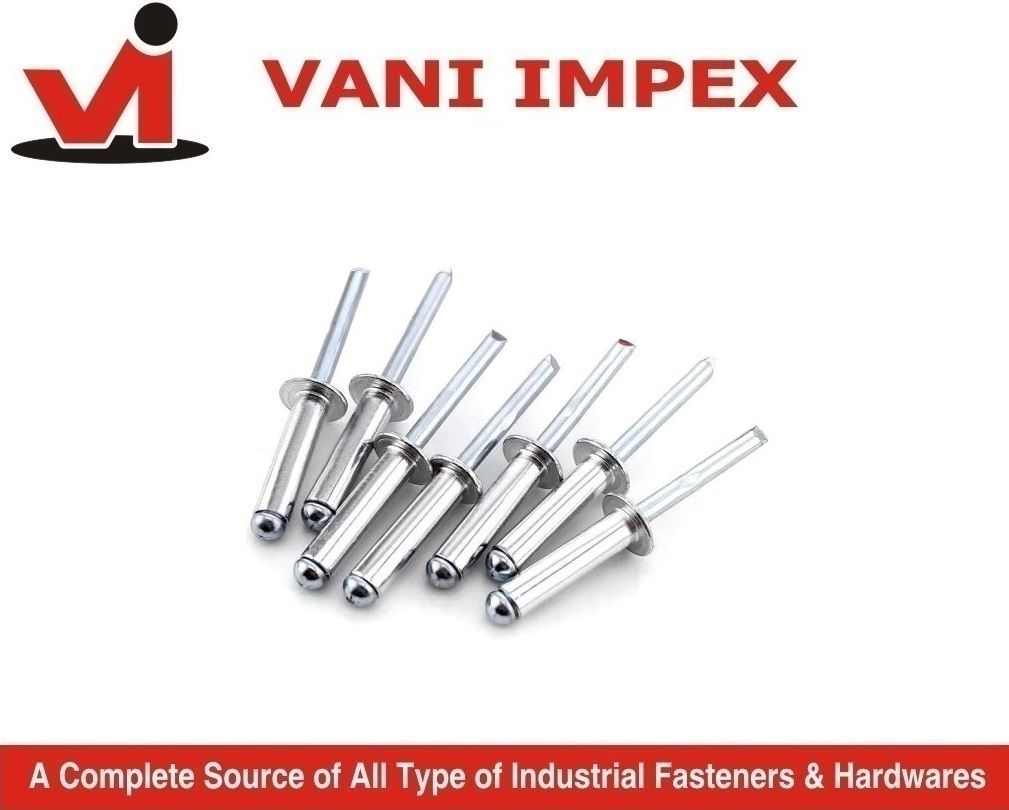

Ss 304 Blind Rivets

Product Details:

- Surface Treatment Polished / Passivated

- Thickness Up to 12 mm grip range (varies with rivet length)

- Torque Not applicable (non-threaded pull type)

- Load Capacity Suitable for medium to heavy duty fastening

- Grade SS 304

- Finish Bright Finish

- Corrosion Resistant Yes, excellent in harsh environments

- Click to View more

X

Ss 304 Blind Rivets Product Specifications

- 0.05 mm

- Up to 12 mm grip range (varies with rivet length)

- Polished / Passivated

- Blind Rivet (Pop Rivet)

- Sheet metal, automotive, electronic enclosures, general fastening

- Min. 550 N/mm2

- Pull/Break Mandrel (Blind setting)

- Suitable for medium to heavy duty fastening

- 3.2 mm, 4.0 mm, 4.8 mm, 6.4 mm (custom sizes available)

- Dome (Standard), Countersunk, Large Flange

- Not applicable (non-threaded pull type)

- DIN 7337 / ISO 15977

- Standard duty

- Non-threaded

- Bright Finish

- SS 304

- Yes, excellent in harsh environments

- Round shaft with set head

- Hardened stainless steel

- Corrosion resistant, vibration resistant

- Stainless Steel 304

Product Description

Ss 304 Blind Rivets

| Size | Dia: 2.4mm to 4.8mm, Length : 6mm to 38mm |

| Material | Stainless Steel |

| Quantity Per Pack | 250/500/100 Pieces |

| Brand | VANI |

| Corrosion Resistance | 100% |

| Length Range | 6mm to 38mm |

| Packaging Type | Box |

| Material Grade : SS 304 | Diameter: 2.4mm to 4.8mm |

Product Description Stainless steel blind meets have the strongest tensile strengths, sheer strengths and mandrel break load standards of all the break mandrel rivets. They resist tarnishing under most atmospheric conditions and offers high strength at moderately raised temperatures.

Benefits:

- They provide a quick and easy way to join materials.

- Theres no need to worry about tool clearance, rotation failures, secondary parts and more when using a Blind rivet.

- Theres no risk or stripping or under-torgueing.

- The rivet wont loosen or shake out once installed.

Available Sizes:

2.4X6 mm

- 2.4X8 mm

- 2.4X10 mm

- 3.2X6 mm

- 3.2X8 mm

- 3.2X10 mm

- 3.2X12 mm

- 3.2X16 mm

- 3.2X19 mm

- 4X6 mm

- 4X8 mm

- 4X10 mm

- 4X12 mm

- 4X16 mm

- 4X20 mm

- 4.8X10 mm

- 4.8X12 mm

- 4.8X16 mm

- 4.8X20 mm

- 4.8X25 mm

- 4.8X32 mm

- 4.8X38 mm

Superior Performance in Demanding Environments

SS 304 Blind Rivets stand out for their remarkable corrosion and vibration resistance, making them a wise choice for applications exposed to moisture, chemicals, or temperature extremes between -50C and +250C. Their non-combustible, RoHS compliant construction ensures both fire safety and environmental responsibility.

Versatile and Easy Installation

With compatibility for both manual and pneumatic tools, these rivets simplify assembly lines and field repairs alike. Their easy pull and break mandrel process requires no advanced training, making them practical for both professional technicians and workshop settings.

Reliable Fastening for Multiple Applications

Whether youre working in automotive assembly, electronic enclosures, sheet metal fabrication, or general fastening, SS 304 Blind Rivets ensure secure and reliable connections. They accommodate various head types and grip thicknesses, supporting a wide range of structural needs.

FAQs of Ss 304 Blind Rivets:

Q: How are SS 304 Blind Rivets installed?

A: SS 304 Blind Rivets can be installed using either manual hand tools or pneumatic rivet guns. The process involves placing the rivet in a pre-drilled hole, then pulling the mandrel to expand the rivet shaft and form a secure joint. No threading or specialized training is required.Q: What is the benefit of using SS 304 material in these blind rivets?

A: SS 304 stainless steel offers outstanding corrosion and vibration resistance, ensuring long-lasting durability even in harsh or outdoor environments. It is also non-combustible and provides excellent strength for medium to heavy-duty fastening.Q: When should I use a dome, countersunk, or large flange head rivet?

A: Choose the dome head for standard applications, countersunk for flush mounting and minimal protrusion, and large flange for increased bearing surface in softer or thinner materials. The head type should match your assemblys structural requirements.Q: Where are SS 304 Blind Rivets commonly applied?

A: These rivets are ideal for use in automotive assembly, sheet metal fabrication, electronics enclosures, and general fastening tasks across diverse industries, especially where reliability under vibration and exposure to moisture or chemicals is needed.Q: What grip range and sizes are available for these rivets?

A: SS 304 Blind Rivets offer a grip range up to 12 mm, with rivet lengths from 6 mm to 24 mm and diameters from 3.2 mm to 6.4 mm. Custom sizes can also be supplied to fit specific applications.Q: Are these rivets compliant with international standards?

A: Yes, these rivets are manufactured according to DIN 7337 and ISO 15977 standards, ensuring quality, performance, and compatibility for global markets. They are also RoHS compliant for environmental safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free