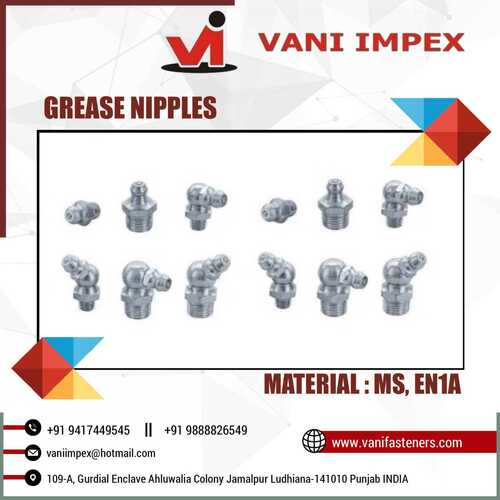

Grease Nipples

Product Details:

- Hardness Rockwell 70 HRB

- Thickness Up to 2 mm

- Corrosion Resistant Yes

- Torque Up to 20 Nm

- Diameter M6, M8, M10 (custom sizes available)

- Tensile Strength 580 MPa

- Finish Polished, Coated

- Click to View more

X

Grease Nipples Product Specifications

- Up to 2 mm

- Rockwell 70 HRB

- Polished, Coated

- Suitable for high-pressure lubrication

- Lubrication and grease fittings

- Round, Hex

- Leak-proof, Durable, Easy to install

- Yes

- 0.01 mm

- Varied shapes available

- Steel, Brass, Stainless Steel

- Zinc Plated, Nickel Plated, Chrome Plated

- Metric, BSP, NPT

- M6, M8, M10 (custom sizes available)

- DIN 71412

- A2, A4

- Grease Nipple

- Up to 20 Nm

- Up to 4,000 psi

- 580 MPa

- Internal or External Hex

- Silver, Golden

- Automobile, Industrial machinery, Agricultural equipment

- Over 10,000 cycles

- Plastic bag, Box, or as required

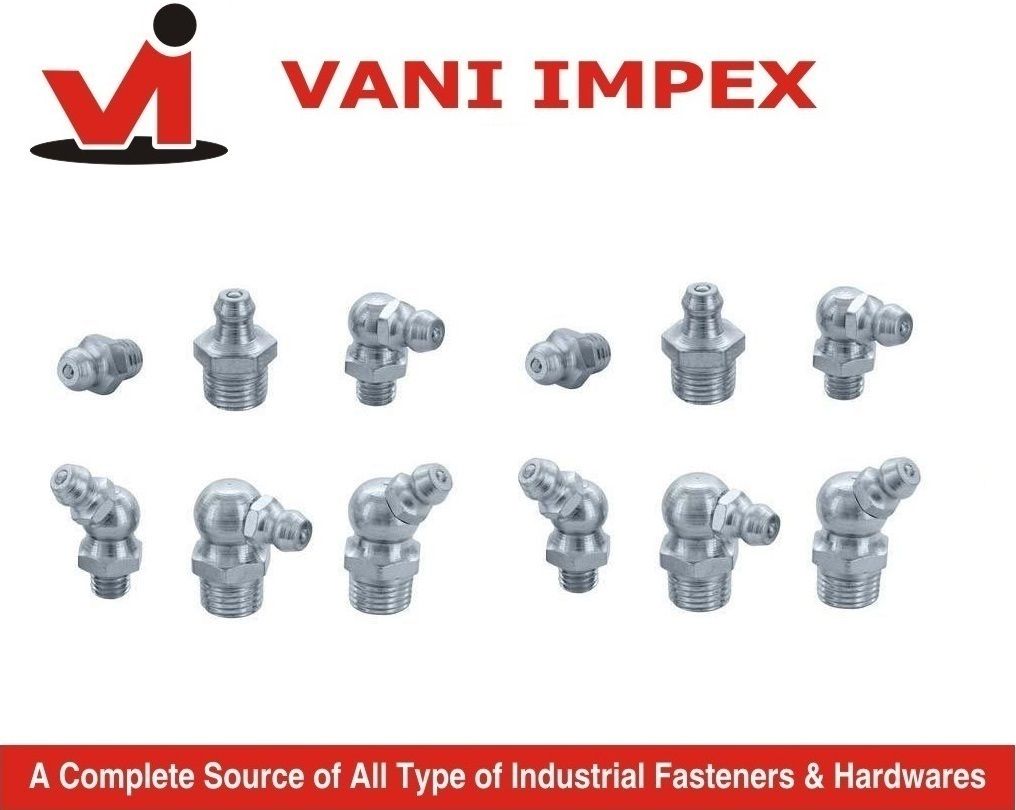

- Straight, 45°, 90° Angled

- Available

- -20°C to +250°C

- Threaded

Product Description

Grease Nipples

|

Size |

6 mm to 12 mm |

|

Material |

Steel |

|

Brand |

Vani |

|

Head |

Conical, Hexagonal, Square |

|

Usage/Application |

Gearbox, Bearing |

|

Country of Origin |

Made in India |

We are manufacturer and suppliers of all kinds of Grease Nipples,Button Head Grease Nipples, Pin Type Grease Nipples and Grease Gun Couplers.

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: BOXES

Reliable Lubrication for Your Equipment

Grease nipples are essential for maintaining optimal performance in machines, reducing friction and wear during operation. Compatible with both industrial and automotive settings, these fittings make frequent lubrication processes more efficient, ultimately extending the life of expensive equipment. Their high load capacity and corrosion resistance ensure consistent performance in demanding environments.

Variety of Shapes and Materials

Available in straight, 45, or 90 angled forms, grease nipples adapt to specific installation needs. Choose from durable steel, brass, or stainless steel materials, each offering excellent strength and resistance to harsh conditions. Custom diameters (M6, M8, M10) and various head types (round, hex) guarantee optimal fit and performance, no matter the machinery.

FAQs of Grease Nipples:

Q: How do I select the appropriate grease nipple type for my machinery?

A: To choose the right grease nipple, consider the access angle required for lubricationstraight, 45, or 90and confirm compatibility with your equipments thread type (Metric, BSP, or NPT). Assess the operating temperature and pressure, as well as the material and size specifications, for optimal performance and longevity.Q: What applications are grease nipples suitable for?

A: Grease nipples are widely used in lubrication systems for automobiles, industrial machinery, and agricultural equipment. Their design ensures efficient delivery of grease to moving parts, helping minimize wear and extend maintenance intervals.Q: When should grease nipples be replaced?

A: Replace grease nipples if they show signs of leakage, clogging, or mechanical damage, or after consistent use beyond their rated life cycletypically over 10,000 cycles. Regular inspection ensures proper lubrication and helps prevent machinery failure.Q: Where can I install angled grease nipples in my equipment?

A: Angled grease nipples (45 and 90) are ideal for lubrication points with restricted space or hard-to-reach areas, allowing grease access without disassembling machinery parts. Straight types are best for direct and unobstructed fittings.Q: What benefits do OEM services offer for grease nipples?

A: OEM services allow for custom manufacturing of grease nipples tailored to your specificationssuch as unique diameters, shapes, materials (steel, brass, stainless steel), or surface treatmentsmatching the exact needs of your machinery and enhancing maintenance efficiency.Q: How are grease nipples installed and maintained?

A: Grease nipples are threaded into pre-drilled fittings using their internal or external hex drive. Regular cleaning and lubrication prevent clogging, and timely replacement guarantees leak-proof operation. Maintenance ensures their durability and corrosion resistance.Q: What is the advantage of using corrosion-resistant grease nipples?

A: Corrosion-resistant grease nipples, treated with zinc, nickel, or chrome plating, ensure long-term operation in harsh environments and protect against rust and chemical exposure. This extends service life and maintains consistent lubrication for high-performance equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free