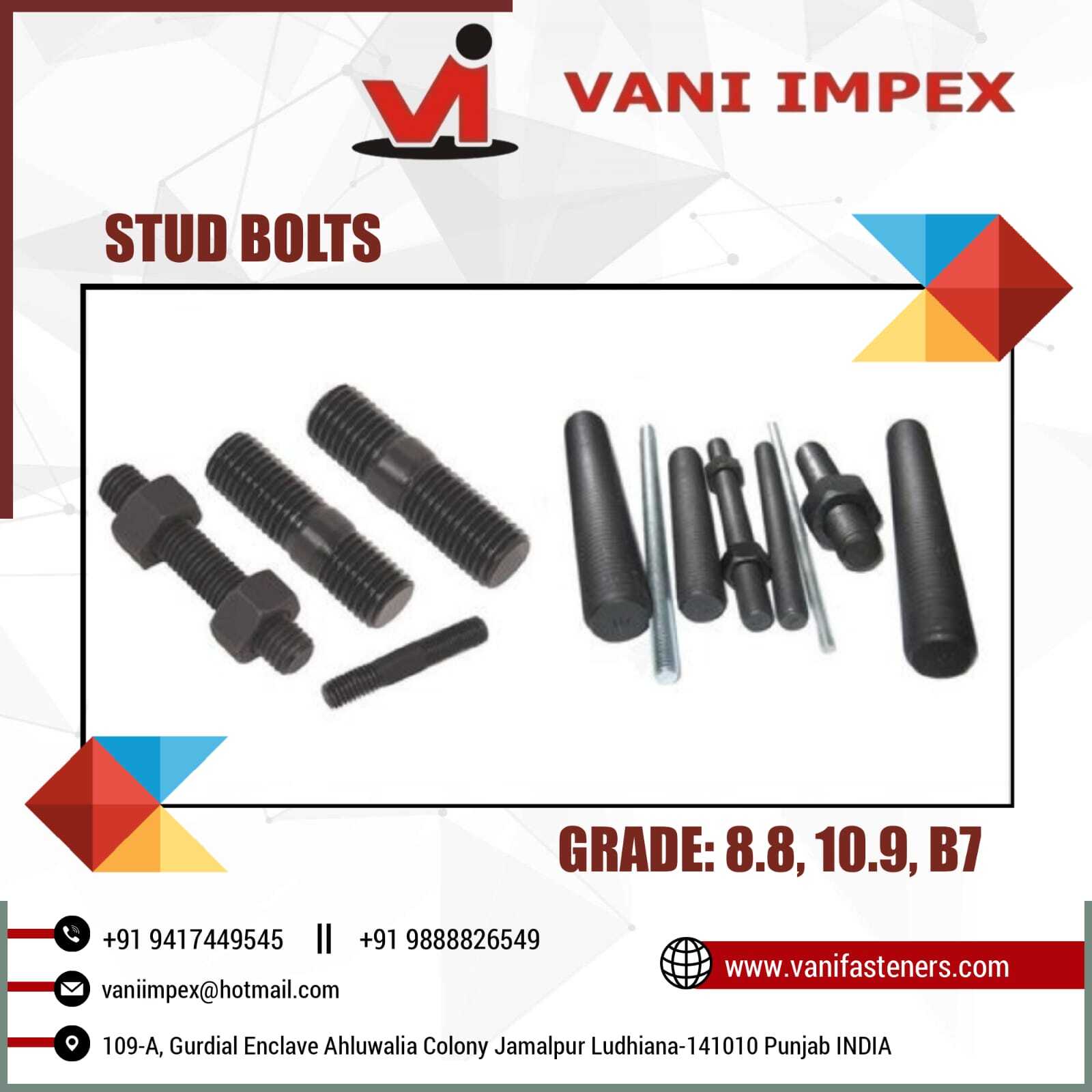

Stud Bolts

Product Details:

- Thread Type Metric, UNC, UNF, BSW

- Capacity High fastening capacity

- Tensile Strength Minimum 400 MPa to 1000 MPa depending on grade

- Thickness As per diameter, up to 6 mm

- Corrosion Resistant Yes, with surface treatment

- Head Type Without head (stud design)

- Diameter M8 to M56

- Click to View more

Stud Bolts Price And Quantity

- 1000 Kilograms

- 130.00 - 180.00 INR/Kilograms

Stud Bolts Product Specifications

- Without head (stud design)

- Bright, Matte, Black

- Cylindrical

- Threaded, no drive head

- M8 to M56

- Up to 38 HRC depending on grade

- High strength, robust performance, precision threads

- Max 60 Nm to 600 Nm depending on size

- Up to 20000 kg (varies by size and material)

- 0.02 mm

- Hot Dip Galvanized, Zinc Plated, Black Oxide

- 4.6, 8.8, 10.9, B7

- Minimum 400 MPa to 1000 MPa depending on grade

- High fastening capacity

- Metric, UNC, UNF, BSW

- Carbon Steel, Alloy Steel, Stainless Steel

- As per diameter, up to 6 mm

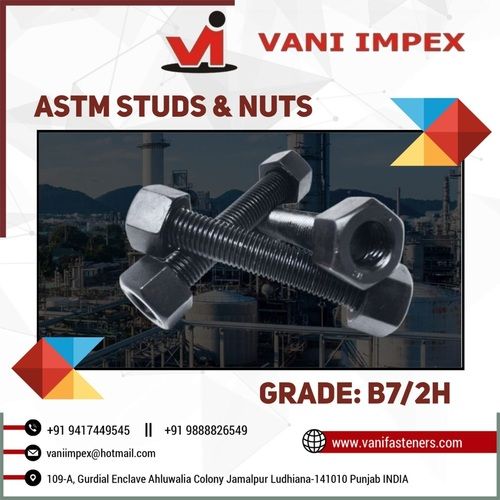

- ASTM A193, ASTM A194, DIN 976, IS 1367

- Stud Bolt

- Petrochemical, Oil & Gas, Power Plants, Construction, Automobile

- Yes, with surface treatment

Product Description

Stud Bolts

|

Usage/Application |

Industrial |

|

Standard |

ASTM |

|

Product Type |

Threaded |

|

Size |

M 16 TO M 48 |

|

Material |

Carbon Steel |

|

Grade |

B7, 8.8, 10.9 |

|

Finish |

Black |

|

Color |

Black |

|

Surface Treatment |

Black |

We manufacture, supply,distribute and export a wide assortment of Full Thread Studs. Our offered range is manufactured using superior quality metals that are sourced from vendors of high repute. These thread studs are applauded in market for their High Tensile Strength, Fine Finish, Corrosion Resistance and Dimensional Accuracy. Moreover, we customize these as per the specifications detailed by clients.

Specifications:

Grades: B7, B7M, L7, L7M,2H, 2HM, G4, G7, B8, B8M, 8M, 8, Gr8, B5, Gr. A, B

Standards:

IS: 4.6, 5.6, 6.8, 8.8, 10.9, 12.9, 4, 5,6, 8, 10, 12

IS: 1862, B1.1, B18.2.1

ASTM studs

Additional Information:

Delivery Time: 30 DAYS

Packaging Details: BAGS

Precision Crafted for Critical Applications

Engineered to meet the strictest standards, our stud bolts ensure reliable performance in high-load and high-temperature environments. Carefully forged and tested, each bolt offers robust fastening solutions for industries where safety and durability are paramount. With wide material and surface treatment choices, we deliver tailored solutions for specialized requirements.

Versatile Sizing and Customization

Available in lengths from 40 mm up to 2000 mm and diameters ranging from M8 to M56, our stud bolts adapt to a wide array of project needs. Custom sizes and non-standard thread directions (right or left hand) are also offered to accommodate unique design or installation scenarios, ensuring flexibility for any application.

Superior Corrosion and Temperature Resistance

A variety of hot dip galvanized, zinc plated, and black oxide coatings make these bolts rust-proof and fit for use up to 400C. Resistant to tough industrial conditions, our stud bolts provide long service life and consistent performance, reducing maintenance needs and replacement cycles.

FAQ's of Stud Bolts:

Q: How are the stud bolts manufactured and inspected?

A: The stud bolts are produced using both cold forging and hot forging processes, depending on the material and dimension. Each bolt undergoes rigorous dimensional, mechanical, and visual inspections to ensure adherence to a strict tolerance of 0.02 mm.Q: What makes these stud bolts suitable for high-stress industrial environments?

A: With grades such as 4.6, 8.8, 10.9, and B7, and tensile strength ranging from 400 MPa to 1000 MPa, these bolts deliver high fastening capacity and robust performance, making them ideal for power plants, petrochemical industries, and heavy construction applications.Q: Can I request custom sizes and thread types for specific projects?

A: Yes, custom sizes are available on request, and the bolts can be supplied with metric, UNC, UNF, or BSW threads, as well as both right and left hand thread directions to suit various installation requirements.Q: When should I use left-hand thread stud bolts?

A: Left-hand thread stud bolts are used in assemblies where rotation or movement could loosen standard right-hand threads, such as in certain engine, piping, or vibration-prone applications, enhancing joint security.Q: What benefit does the surface treatment provide to the stud bolts?

A: Surface treatments like hot dip galvanization, zinc plating, and black oxide improve the bolts' rust and corrosion resistance, ensuring reliable operation in harsh or outdoor environments and extending service life.Q: Where are these stud bolts most commonly used?

A: They are widely utilized in petrochemical plants, oil & gas installations, power generation facilities, construction sites, and automotive manufacturing, where high strength and durability are crucial.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free