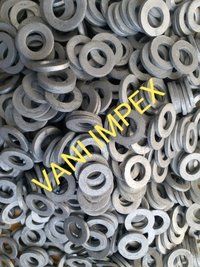

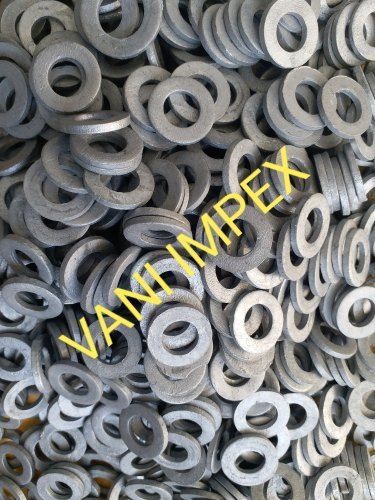

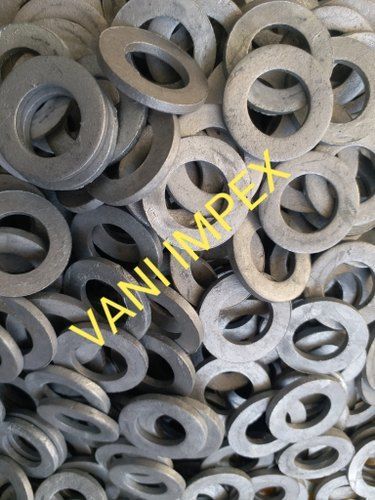

Hardened Flat Washers (300hv) Hdg / Din 125a / Iso 7089 Washers 300hv Hdg

Product Details:

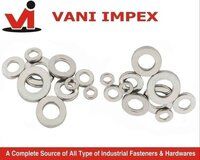

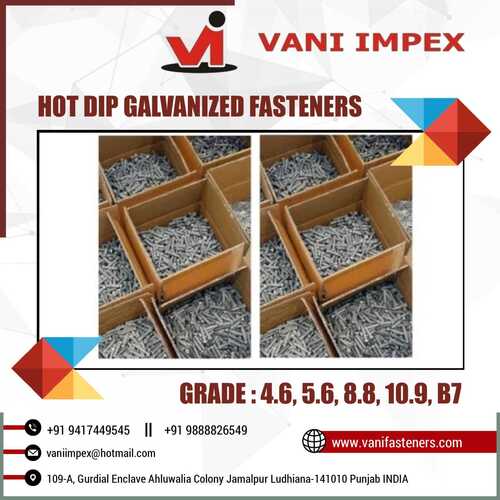

- Finish Zinc Coated, Hot Dip Galvanized

- Surface Treatment Hot Dip Galvanized (HDG)

- Load Capacity Suitable for high hardness requirements

- Standard DIN 125A / ISO 7089

- Shape Round

- Corrosion Resistant Yes (HDG ensures corrosion resistance)

- Feature Hardened, corrosion-resistant, increases load distribution

- Click to View more

X

Hardened Flat Washers (300hv) Hdg / Din 125a / Iso 7089 Washers 300hv Hdg Price And Quantity

Hardened Flat Washers (300hv) Hdg / Din 125a / Iso 7089 Washers 300hv Hdg Product Specifications

- Round

- Yes (HDG ensures corrosion resistance)

- Not applicable (non-load bearing part)

- Hardened, corrosion-resistant, increases load distribution

- Suitable for high hardness requirements

- Hot Dip Galvanized (HDG)

- Zinc Coated, Hot Dip Galvanized

- Structural fastening, machinery, construction, automotive

- DIN 125A / ISO 7089

- 300 HV

- DIN 125A standard tolerances

- Flat Washer

- N/A (washer is not torqued directly)

- Flat

- Standard mechanical fastening

- 300 HV min.

- 0.5 mm to 6 mm (size dependent)

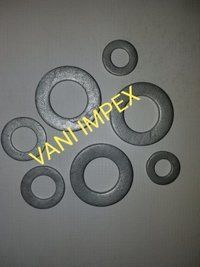

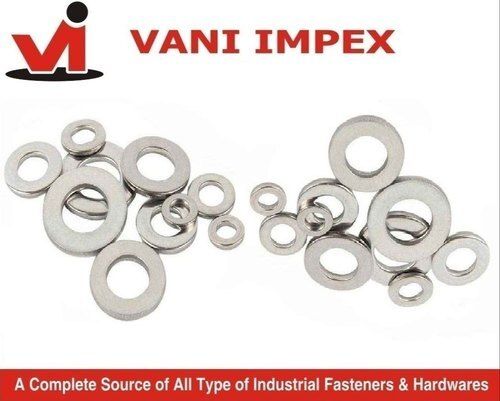

- M6 to M56 (customizable)

- Alloy Steel / Carbon Steel

Product Description

Hardened Flat Washers (300HV) HDG / Din 125A / ISO7089 Washers 300HV HDG

| Material | EN8/EN19 |

| Surface Finish | HDG/TZN |

| Dimension/Size | M 6 TO M 72 |

| Brand | VANI |

| Shape | Round |

| Packaging Type | BAGS/BOXES |

| Material Grade | 8.8/10.9 |

| I Deal In | New Only |

| Country of Origin | Made in India |

Hardened flat washers (300hv) hdg

din 125a (300hv) hdg

iso 7089 washers (300hv) hdg

dia : m 6 to m 72

moq : 250kg each size

Additional Information:

- Production Capacity: 500000PCS

- Delivery Time: 20 - 25 DAYS

- Packaging Details: BAGS/BOXES

Robust Construction for Structural Applications

These flat washers deliver consistent performance in critical structural, automotive, and machinery fastening tasks. With a minimum hardness of 300 HV, they are designed to increase bearing surface area and protect fastener integrity, helping prevent embedment and deformation under heavy loads. Their corrosion-resistant hot dip galvanized coating ensures durability in harsh environments.

Standards-Compliant and Versatile Sizing

Manufactured to ISO 7089, DIN 125A, and EN 14399-6 standards, these washers meet strict tolerance and quality requirements. The diameter range spans from M6 to M56, and can be customized for a variety of bolted assemblies. Thickness and sizing are tailored to suit the mechanical demands of different projects, ensuring broad compatibility.

FAQs of Hardened Flat Washers (300hv) Hdg / Din 125a / Iso 7089 Washers 300hv Hdg:

Q: How are Hardened Flat Washers (300 HV) HDG used in fastening applications?

A: These washers are primarily employed alongside bolts and nuts to evenly distribute load, reduce surface wear, and prevent damage to fastened materials in structural, construction, machinery, and automotive settings.Q: What is the benefit of the hot dip galvanized (HDG) finish on these washers?

A: The HDG coating provides robust corrosion resistance, significantly extending washer lifespan especially in outdoor or challenging environments where moisture or chemicals may be present.Q: When should I choose a 300 HV washer over regular flat washers?

A: Select 300 HV hardened washers for projects requiring high hardness, improved load-bearing surfaces, or compliance with standards like ISO 7089 and DIN 125A, particularly in structural or heavy-duty mechanical connections.Q: Where can these washers be applied?

A: They are used in a wide range of sectors including construction, machinery, automotive, steel structures, and any installation requiring enhanced load distribution and durability.Q: What process is followed for manufacturing these washers?

A: The washers are fabricated from alloy or carbon steel, hardened to a minimum of 300 HV, precision-cut to conform with standard tolerances, and then coated with hot dip galvanization for superior corrosion resistance.Q: How does standard compliance impact washer performance?

A: Compliance with DIN 125A, ISO 7089, and EN 14399-6 ensures consistent dimensional tolerances, material quality, hardness, and safety in demanding fastening situations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free