कॉलर नट्स के साथ डबल एंडेड स्टड

उत्पाद विवरण:

- तरीका Cold Forged and Threaded

- लोड क्षमता Up to 20 metric tons

- आयाम (एल* डब्ल्यू* एच) Standard sizes available (M8-M36, Length 50mm-300mm)

- वाहन का प्रकार Suitable for trucks, trailers, commercial vehicles

- सतह का उपचार Zinc Plated / Black Oxide Coated

- कामकाजी जीवन Up to 50,000 cycles

- मॉडल नं DE-Stud-CN2024

- अधिक देखने के लिए क्लिक करें

X

कॉलर नट्स के साथ डबल एंडेड स्टड मूल्य और मात्रा

कॉलर नट्स के साथ डबल एंडेड स्टड उत्पाद की विशेषताएं

- Automotive, heavy machinery, industrial equipment

- DE-Stud-CN2024

- Yes, with surface coating

- High Tensile Steel

- Stud Bolt with Collar Nuts

- -40°C to +150°C

- Mechanical (Non-Electrical)

- Silver / Metallic Grey

- Pre-lubricated threads

- Varies as per size (Typically 50-500 grams per piece)

- Up to 20 metric tons

- Cold Forged and Threaded

- Threaded (Double Ended)

- Smooth, Corrosion Resistant

- Suitable for trucks, trailers, commercial vehicles

- Standard sizes available (M8-M36, Length 50mm-300mm)

- Zinc Plated / Black Oxide Coated

- Double Ended Stud With Collar Nuts

- M8-M36, Custom sizes available

- Up to 50,000 cycles

- Silent Operation

उत्पाद वर्णन

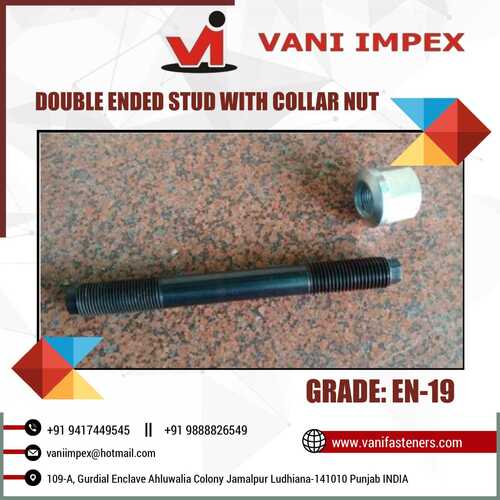

Double Ended Stud With Collar Nuts

EN-19 DOUBLE ENDED STUDS WITH COLLAR NUTS

GRDAE: EN-18, EN-19

RANGE: M 12 TO M 48

LENGTH: 100MM TO 500MM

FINISH: BLACK, ZINC, HDG

|

Material |

EN-19 |

|

Quantity Per Pack |

100 |

|

Color |

BLACK |

|

Brand |

VI |

|

Coatings |

AUTO BLACK,ZINC PLATED,HOT DIP GALVANIZED |

|

Grade |

B7,8.8,10.9 |

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: GUNNY BAGS, CARTONS

Superior Strength and Durability

Built from high tensile steel and subjected to rigorous heat treatment and testing, these double ended studs with collar nuts provide exceptional mechanical strength, enduring working loads of up to 20 metric tons. Their robust construction ensures a long working life and silent, maintenance-free operation, making them ideal for tough industrial and automotive environments.

Precision Engineering and Versatility

Conforming to DIN 939/976 and ISO 898-1 standards, these fasteners are designed for versatility across various machinery, flanges, and manifold connections. Their double ended, threaded design with pre-lubricated threads ensures reliable and quick assembly in trucks, trailers, and heavy equipment, adapting to both fine and coarse metric thread requirements.

Quality, Testing, and Customization

Every stud and collar nut undergoes 100% quality control for thread accuracy and hardness. Surface treatments like zinc plating and black oxide coating deliver corrosion resistance, while custom size production (M8-M36, lengths up to 300mm) supports specialized application needs. Reliable supply is assured with a monthly capacity of 100,000 pieces and diverse export packaging options.

FAQ's of Double Ended Stud With Collar Nuts:

Q: How are double ended studs with collar nuts typically used in automotive and industrial equipment?

A: These studs securely join flanges, manifolds, and assemblies in vehicles, heavy machinery, and industrial systems. Their double-ended threaded design allows attachment from both ends, providing a strong, reliable connection that withstands high loads and vibrations.Q: What are the primary benefits of the collar nut with a hexagonal head?

A: The collar nut with a hexagonal head permits easy tightening using standard tools, ensures uniform load distribution, and minimizes the risk of loosening, contributing to secure and stable mechanical assemblies over extended operational cycles.Q: Where do these double ended studs with collar nuts find applications?

A: They are widely used in automotive sectors (such as trucks, trailers, and commercial vehicles), heavy machinery, industrial equipment, and wherever high tensile fastening and corrosion resistance are critical requirements.Q: What quality control measures are in place during production?

A: Every piece is subjected to 100% thread inspection and hardness testing. The production process includes heat treatment and cold forging to enhance mechanical properties, along with surface treatments for lasting corrosion resistance.Q: How do surface treatments like zinc plating and black oxide coating enhance product performance?

A: Zinc plating and black oxide coating shield the fasteners from corrosion and environmental factors, extending service life and reliability-even under harsh operational conditions or fluctuating temperatures.Q: Can I order custom sizes for specific project requirements?

A: Yes, custom sizes within the M8-M36 diameter range and lengths from 50mm to 300mm are available upon request to match unique project needs or specifications.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें