एचडीजी कैरिज बोल्ट

उत्पाद विवरण:

- लोड क्षमता Depends on size and grade

- संक्षारण प्रतिरोधी Yes

- टेन्साइल स्ट्रेंथ 400 – 800 MPa

- फ़िनिश करें Galvanized

- सतह का उपचार

- फ़ीचर Rust Resistant, Durable

- हेड टाइप Round

- अधिक देखने के लिए क्लिक करें

X

एचडीजी कैरिज बोल्ट मूल्य और मात्रा

एचडीजी कैरिज बोल्ट उत्पाद की विशेषताएं

- Plain (No Drive)

- M6 to M20

- ±0.3 mm

- Depends on size and grade

- DIN 603, IS 2629, ASTM A307

- As per diameter and grade

- Yes

- Galvanized

- 400 – 800 MPa

- As per size and standard

- Round Head, Square Neck

- Construction, Industrial Fittings, Wood Jointing

- 40–50 HRC

- Rust Resistant, Durable

- As per standard

- Round

- 4.6, 8.8, 10.9

उत्पाद वर्णन

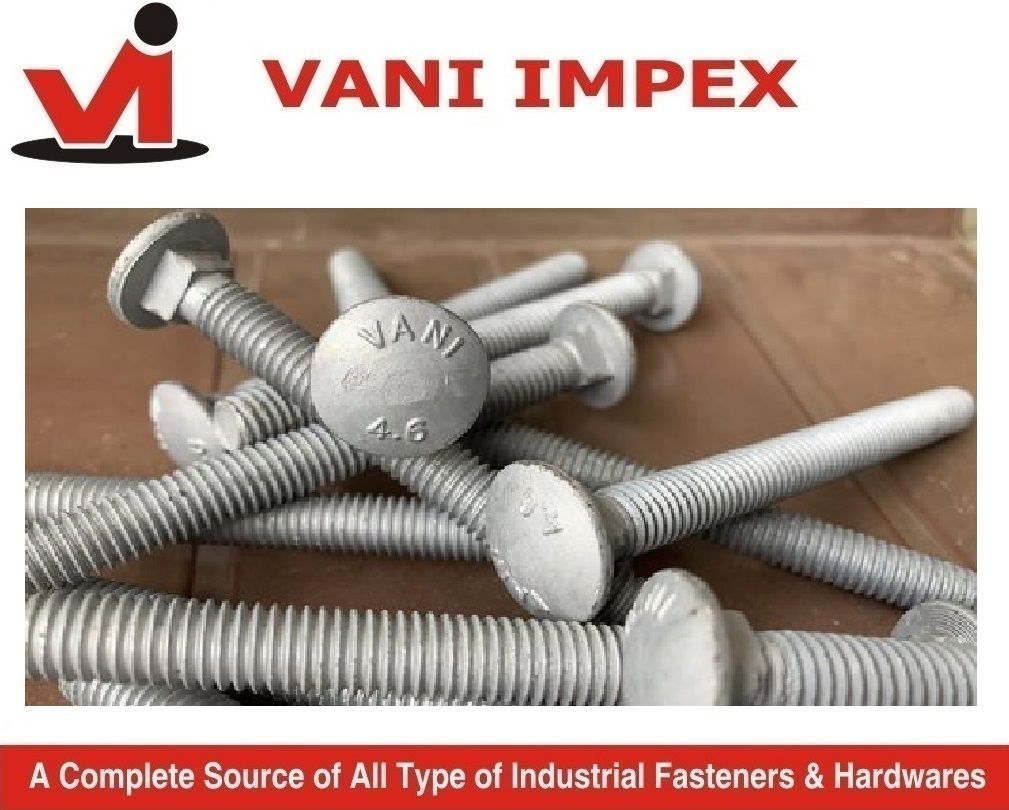

Hdg Carriage Bolt

| Size | DIA : M 6 to M 12,1/4" to 1/2",Length: 25mm to 150mm,1/2" to 6" |

| Material Grade | 4.6,5.6,A307,8.8,10.9 |

| Brand | VANI |

| Type Of Bolts | Round-head |

| Packaging Type | Square Neck Round Head |

| Surface Finish | Auto Black,Zinc,HDG |

| Type Of Coating | HDG |

| Material Type | MS,EN8,EN18 |

| Diameter | M 6 to M 12,1/4" to 1/2" |

| I Deal In | New Only |

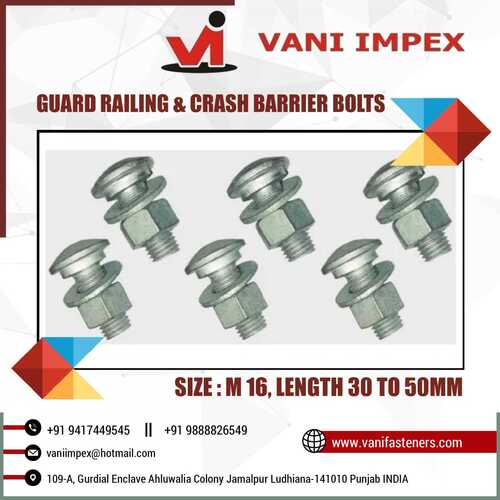

HDG CARRIAGE BOLTS

We offer a wide variety of CARRIAGE BOLTS

Diameter: METRIC 6MM to 12MM & IN INCHES 1/4" to 1/2"

Length: METRIC 25MM to 150MM & IN INCHES 1" to 6" Full Thread and Half Thread

Robust Performance for Demanding Applications

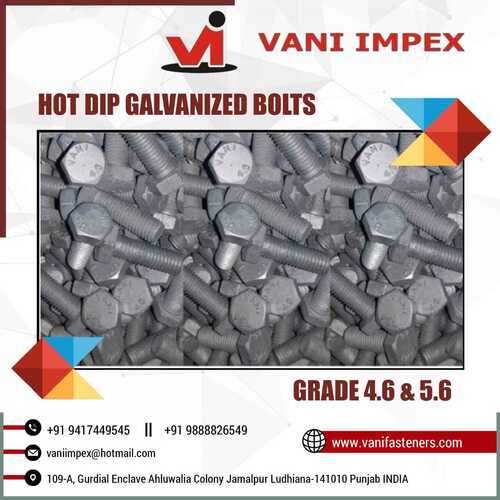

Engineered for strength and durability, these HDG Carriage Bolts are ideal for heavy-duty fastening in diverse industrial and structural settings. The high tensile strength and rust-resistant galvanized finish ensure long-lasting reliability, even in challenging environments. Choose from multiple grades and sizes to suit project-specific requirements.

Precision Manufacturing & Versatile Design

Every bolt is produced using advanced cold or hot forging techniques that deliver precise tolerances (0.3 mm) and consistent quality. The round head and square neck design prevent rotation during installation, making them exceptionally easy to use in construction, woodwork, and industrial applications.

Superior Protection and Easy Logistics

Hot dip galvanization offers enduring protection against rust and corrosion, extending the lifespan of each fastener. Multiple packaging choicesjute bags, cartons, or wooden boxesfacilitate safe transport and handling, whether youre sourcing domestically or exporting. Capacity and load are tailored as per size, grade, and application.

FAQs of Hdg Carriage Bolt:

Q: How are HDG Carriage Bolts manufactured and what standards do they meet?

A: HDG Carriage Bolts are produced using cold or hot forging techniques from mild or carbon steel, ensuring accurate dimensions with a 0.3 mm tolerance. They adhere to recognized standards such as DIN 603, IS 2629, and ASTM A307, guaranteeing reliability and uniformity in performance.Q: What are the main uses and benefits of HDG Carriage Bolts?

A: These bolts excel in heavy-duty fastening within construction, industrial fittings, and wood jointing projects. Benefits include robust tensile strength (400800 MPa), resistance to corrosion due to hot dip galvanization, and dependable durability in demanding environments.Q: Where can HDG Carriage Bolts be installed and what makes them advantageous for such applications?

A: They are suitable for use in construction sites, manufacturing facilities, and any environment requiring secure, rust-resistant fastening. Their round head and square neck prevent rotational movement, while the galvanized finish enhances lifespan, making them advantageous for both indoor and outdoor use.Q: What is the recommended process for selecting the correct HDG Carriage Bolt for a project?

A: Determine the required diameter (M6 to M20), length (20300 mm), and grade (4.6, 8.8, or 10.9) based on the load and environmental factors. Ensure the selected bolt matches the applications tensile strength, temperature resistance, and standard metric thread requirements.Q: How does hot dip galvanization benefit the performance of these carriage bolts?

A: Hot dip galvanization significantly enhances the bolts resistance to rust and corrosion, making them suitable for outdoor and high-moisture environments. This coating protects the steel substrate, ensuring the bolts remain structurally sound over an extended period.Q: What packaging options are available and when should each be chosen?

A: Depending on logistics and handling needs, bolts can be packed in jute bags, cartons, or wooden boxes. Jute bags are ideal for large, bulk shipments; cartons are suited for moderate quantities; while wooden boxes offer maximum protection for export or long-distance transport.Q: What is the minimum order quantity and typical lead time for HDG Carriage Bolts?

A: The minimum order quantity (MOQ) is 1,000 pieces. Lead time may vary based on order size, specifications, and customization, with timelines set according to manufacturing capacity and standards. For precise delivery estimates, please contact the supplier directly.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें