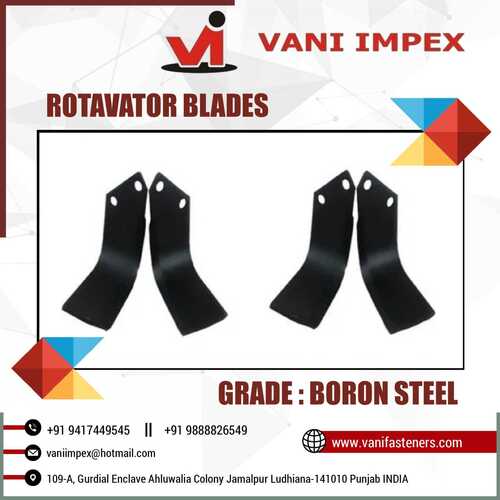

रोटावेटर ब्लेड

उत्पाद विवरण:

- शोर का स्तर Low (depends on overall machine)

- उपयोग/अनुप्रयोग Land tilling, seedbed preparation, weed control

- शेप L-Type or C-Type curve

- टूल टाइप Rotavator Blade

- विशेषताएँ Heat treated, wear-resistant, easy to install, sharp cutting edge

- प्रॉडक्ट टाइप Agricultural Implement Blade

- सामान्य उपयोग Agricultural soil preparation and tilling

- अधिक देखने के लिए क्लिक करें

X

रोटावेटर ब्लेड मूल्य और मात्रा

रोटावेटर ब्लेड उत्पाद की विशेषताएं

- Varies as per rotavator (typically 1.2 to 2.2 meter width)

- Depends on tractor PTO (540/1000 RPM)

- Black, Blue or as per manufacturer finish

- Agricultural Implement Blade

- Rotavator Blade

- Heat treated, wear-resistant, easy to install, sharp cutting edge

- Agricultural soil preparation and tilling

- Approx. 250-350 mm (Length), 60-80 mm (Width), 6-8 mm (Thickness)

- Approx. 1.4 - 2.2 kg per blade

- Low (depends on overall machine)

- L-Type or C-Type curve

- Compatible with 25-60 HP tractors

- High soil pulverization and mixing efficiency

- Land tilling, seedbed preparation, weed control

उत्पाद वर्णन

Rotavator Blade| Model Name/Number | SHAKITMAN, SONALIKA AND ALL OTHER MODELS |

| Material | Boron Steel |

| No. Of Blades | 56, 42, 48 |

| Brand | All Rotavators Shaktiman, Sonalika, Bull, Lancer |

| Blade Type | L TYPE, C TYPE, J TYPE |

| Country of Origin | Made in India |

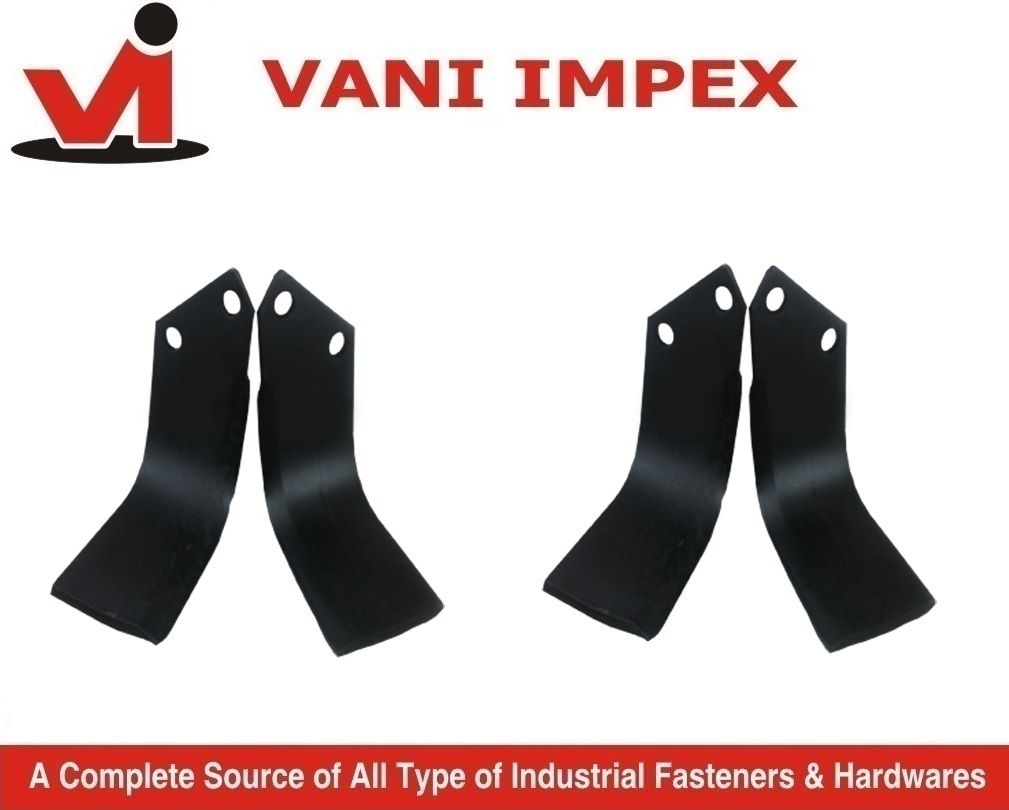

Our accomplished and devoted dexterous experts are occupied in presenting an excellent range of Rotavator Blades. These products are accessible with us in diverse specification that meets on consumers demand. These products are broadly praised by our patrons owing to their longer service life and reliable performance. This entire range of blade is checked on definite industry parameters prior to its dispatch.

Features:

- Easy to operate

- Easy to install

- Longer life service

Additional Information:

- Production Capacity: 10000

- Delivery Time: 2- 4 DAYS

- Packaging Details: CARTON BOXES

Exceptional Durability and Strength

Forged and heat-treated, our rotavator blades deliver outstanding hardness (48-52 HRC) and resilience, making them suitable for demanding farming conditions. The special surface coating ensures superior corrosion resistance, extending blade service life. Each blade is quality-tested to meet industry standards, providing reliable performance for agricultural professionals.

Versatile Design for Diverse Machinery

With mounting hole diameters of 16-18 mm and sets ranging from 36 to 54 blades, these blades fit various rotavator widths and models. Whether you require single or double-edged tips, our range covers multiple variants for compatibility with numerous Indian and international rotavator brands, simplifying procurement and installation for your equipment.

FAQs of Rotavator Blade:

Q: How are the rotavator blades manufactured for enhanced durability?

A: The blades are produced using a forging process followed by heat treatment, resulting in high hardness levels (48-52 HRC). This manufacturing method imparts strength and resistance to wear, enabling the blades to withstand tough soil conditions during rotavation.Q: What is the benefit of black oxide or painted surface finish on the rotavator blades?

A: Black oxide coating or paint provides excellent corrosion resistance, protecting the blades from rust and environmental degradation. This ensures longer operational life and consistent performance in various climates.Q: When should I replace my rotavator blades?

A: Blades should be replaced when you notice a reduction in soil cutting efficiency, excessive wear or visible damage. Regular inspection is recommended to maintain optimal rotavator performance and safeguard equipment longevity.Q: Where can these rotavator blades be installed?

A: The blades are compatible with a wide range of Indian and international rotavator brands. Their mounting hole diameter (16-18 mm) allows them to be installed on various rotavator models, depending on specific requirements.Q: What options are available concerning the number of blades per set and tip type?

A: Blade sets generally contain between 36 to 54 blades, depending on the rotavator width. Tip variants include both single and double-edged designs, allowing users to select according to their operational needs.Q: Can these blades be exported or supplied outside India?

A: Yes, as a distributor, exporter, manufacturer, supplier, and trader in India, we offer these blades for both domestic and international markets, catering to diverse customer needs worldwide.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें