थ्रेड रॉड

उत्पाद विवरण:

- स्टैण्डर्ड DIN 975 / DIN 976 / ASTM A193

- व्यास M6 - M30

- थ्रेड टाइप

- सतह का उपचार

- शेप Cylindrical

- क्षमता Up to 3 meters length

- हेड टाइप No head (threaded all along)

- अधिक देखने के लिए क्लिक करें

थ्रेड रॉड मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- 1000

- किलोग्राम/किलोग्राम,

थ्रेड रॉड उत्पाद की विशेषताएं

- As per diameter specification

- HRC 18-35

- High strength, Precision threaded

- M6 - M30

- 400 - 1000 MPa

- DIN 975 / DIN 976 / ASTM A193

- Construction, Machinery, Electrical, Plumbing

- Yes

- Up to 3 meters length

- Cylindrical

- ±0.01 mm

- Bright / Matte

- As per grade and application

- 4.6, 5.8, 8.8, 10.9

- No head (threaded all along)

- Depends on diameter and grade

- No drive

उत्पाद वर्णन

Thread Rod|

MILD STEEL |

|

|

Finishing |

ELECTRO ZINC PLATED |

|

Brand |

VI |

|

Quantity Per Pack |

50 KG BUNDLES |

|

Material Grade |

4.6, 5.6, 8.8 |

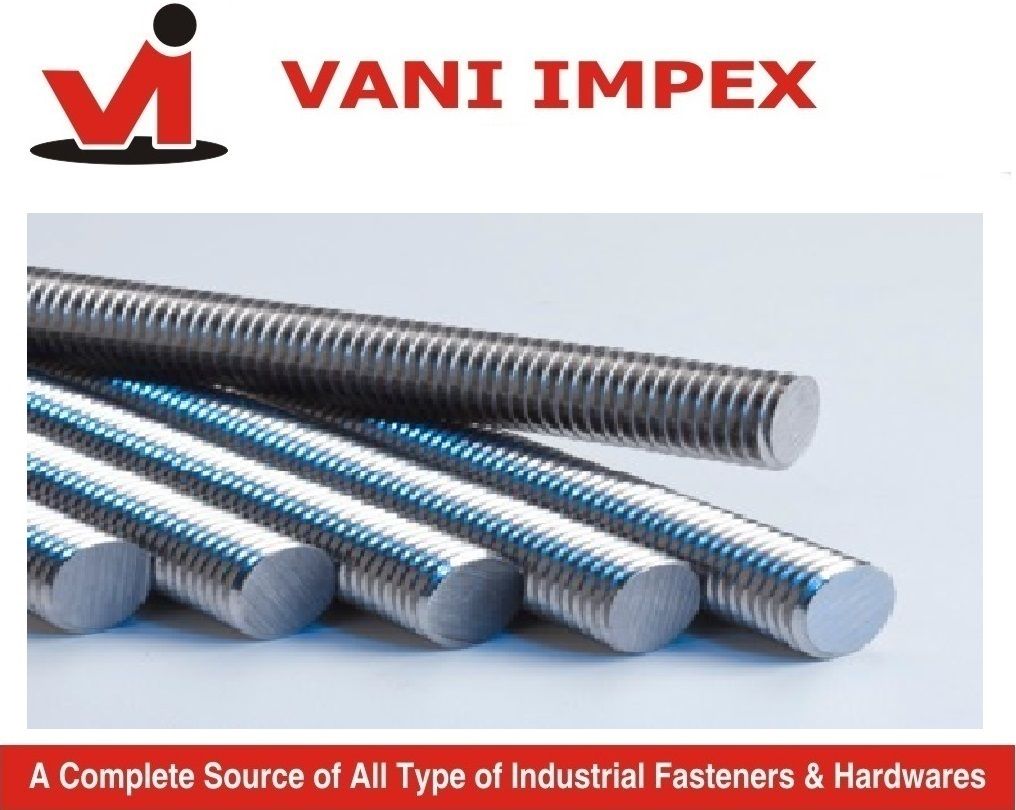

We are appreciated amongst our clients for manufacturing corrosion resistant Threaded Rods with excellent finish. The Thread Rods manufactured by us are being widely used in the Telecom Sector, Construction Industries and in Oil Refineries. These are available with different diameters varying in a range of 6MM - 45MM or 1/4" to 2" and are also known as Thread Bars.

Dia : 6MM - 45MM or 1/4" to 2"

Stock Length : 1METER, 2 METER, 3 METER, 3 FEET, 6FEET,10FEET,12 FEET

Rolled Threads: MM threads, BSW, UNF, UNC, UNEF (V-form)

Grades: These are made of rods with grade 4.8, 5.6, 4.6, 8.8

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: BUNDLES

Precision Engineering and Range

Thread Rods are meticulously manufactured to meet stringent standards, offering diameters from M6 to M30 and lengths up to 3 meters. Standard thread pitch follows DIN and ASTM specifications, with custom pitches, sizes, and thread directions available on request, catering to a wide variety of project needs.

Material Strength and Surface Options

Crafted from carbon or stainless steel, these rods are available in grades 4.6, 5.8, 8.8, and 10.9, ensuring yield strengths suitable for demanding environments. Select from various surface treatmentszinc plated, hot dip galvanized, or plainfor the requisite corrosion resistance and finish, fitting every project requirement.

Application Diversity and Quality Assurance

Ideal for use in construction, industrial machinery, electrical systems, and plumbing, our thread rods provide high strength and precision threading. Every rod undergoes rigorous 100% thread inspection, ensuring exceptional reliability and consistency, suitable for both standard and specialized applications in India and for export markets.

FAQs of Thread Rod:

Q: How are thread rods customized for length, diameter, or thread direction?

A: Thread rods can be customized in length (100 mm to 3,000 mm), diameter (M6M30), and thread direction (right or left hand) based on the projects requirements. Specialized sizes and threading options can be manufactured on request to fit unique application needs.Q: What materials and grades are used for these thread rods?

A: Our thread rods are available in high-strength carbon steel and stainless steel, adhering to international standards (DIN 975 / 976, ASTM A193). Grades such as 4.6, 5.8, 8.8, and 10.9 are offered, ensuring yield strengths from 240 MPa up to 1,050 MPa.Q: When should I opt for different surface treatments?

A: Surface treatments depend on environmental exposure and application. Zinc plating offers basic corrosion protection, hot dip galvanizing provides enhanced durability for outdoor or corrosive environments, and plain finishes suit interior or dry settings where corrosion is minimal.Q: Where are these thread rods typically used?

A: These rods are widely used in construction projects, machinery assembly, electrical installations, and plumbing taskswhere reliable fastening and high load capacity are crucial. Their adaptability makes them suitable for both commercial and industrial sectors.Q: What inspection and quality control processes are implemented?

A: Each thread rod undergoes 100% thread inspection to ensure precise tolerance (0.01 mm) and threading accuracy. Quality is maintained according to DIN and ASTM standards, guaranteeing conformity, safety, and consistent performance in all supplied pieces.Q: How do I determine the correct grade and diameter for my load and torque requirements?

A: The selection of grade and diameter depends on the mechanical load, application, and safety requirements. Consult our technical team with your project details to ensure optimal yield and tensile strength while meeting torque specifications for effective fastening.Q: What are the main benefits of using your thread rods?

A: Our thread rods offer high strength, precision threading, corrosion resistance (with proper surface treatments), and compliance with international standards. These features ensure dependable performance, long service life, and suitability for diverse environments and demanding applications.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें