Machine Screws

Product Details:

- Thickness 2 mm - 30 mm

- Torque Up to 50 Nm

- Drive Type Slotted, Phillips, Hex, Torx

- Finish Polished, Matte, Galvanized

- Grade A2, A4, 8.8, 10.9, 12.9

- Capacity Up to 1500 pieces per hour

- Thread Type Full Thread, Partial Thread, Metric, UNC, UNF

- Click to View more

X

Machine Screws Price And Quantity

- 0.25 mm to 1.5 mm

- 60°

- 4-18 mm

- -40°C to +250°C

- 4 mm to 100 mm

- Box, Bag, Bulk

- Yes

- Silver, Black, Yellow

- Optional (based on material)

Machine Screws Product Specifications

- Precision Threaded, Anti-Loosening, Rust Resistant

- 400-1200 MPa

- Yes

- +/- 0.02 mm

- Up to 1500 pieces per hour

- Full Thread, Partial Thread, Metric, UNC, UNF

- DIN, ISO, ASTM, JIS, BS

- Stainless Steel, Carbon Steel, Brass, Alloy Steel

- A2, A4, 8.8, 10.9, 12.9

- Machine Screws

- Electrical, Machinery, Furniture, Construction, Automotive, General Fastening

- M2 to M10

- Cylindrical

- Up to 50 Nm

- 2 mm - 30 mm

- Slotted, Phillips, Hex, Torx

- Slotted, Phillips, Pozi, Hex, Torx, Countersunk, Pan, Cheese, Round

- Up to 1200 kg

- 20-45 HRC

- Polished, Matte, Galvanized

- Zinc Plated, Black Oxide, Nickel Plated, Chrome Plated

- 0.25 mm to 1.5 mm

- 60°

- 4-18 mm

- -40°C to +250°C

- 4 mm to 100 mm

- Box, Bag, Bulk

- Yes

- Silver, Black, Yellow

- Optional (based on material)

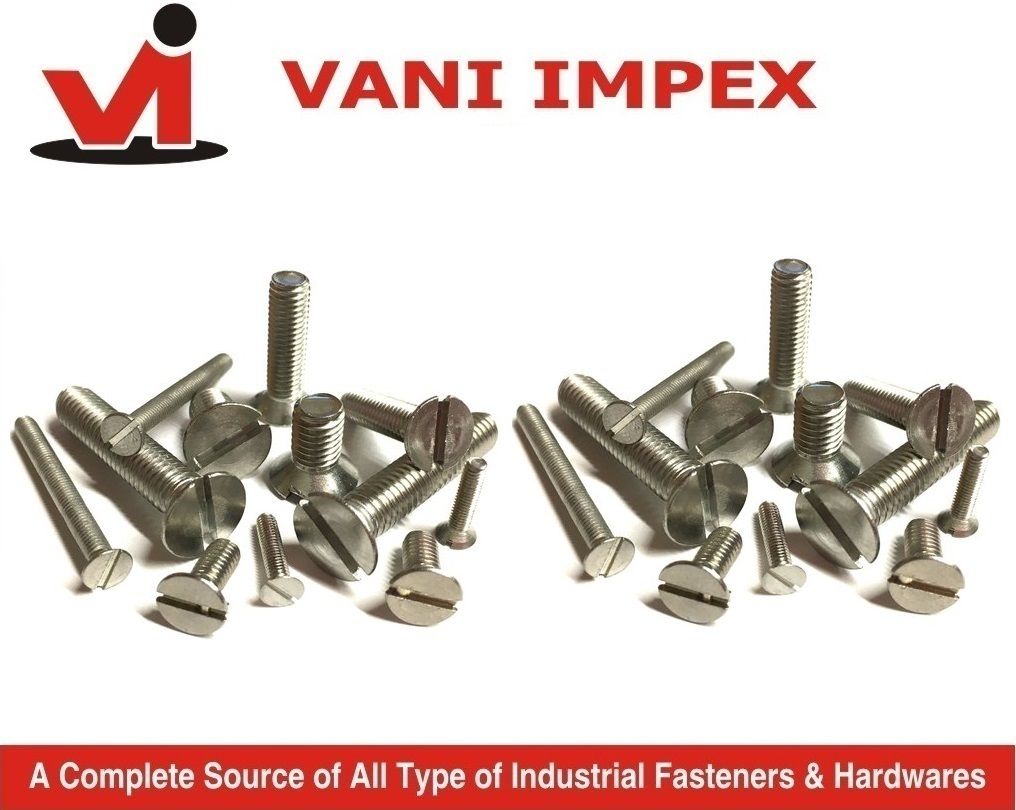

Product Description

We are engaged in manufacturing Machine Screws. Our range of screws includes Slotted and Phillips Head Screws used in fixing or fitting various products. The basic purpose of a screw is for holding all sorts of things together, which include wood, plastic and metal. These are offered at market leading prices to our clients.Machine Screws are in immense demand in the market for the construction of Food processing machinery, Beverage machinery, Pharmaceutical machinery and Electrical appliances. These are available in size: M3 to M6, Material Grades of SS 304.

Availability

- Slotted CSK Screw as per DIN 963

- Slotted Cheese Head Screw as per DIN 84

- Slotted Pan Head Screws as per DIN 85

- Phillips Pan Head Screw as per DIN 7985

- Phillips CSK Head Screw as per DIN 965

- Bright Finishing

- Genuine Grade

- Good Aesthetics Look

- Without Burr

- Accurate Cross Recesses

- Easy Tightening

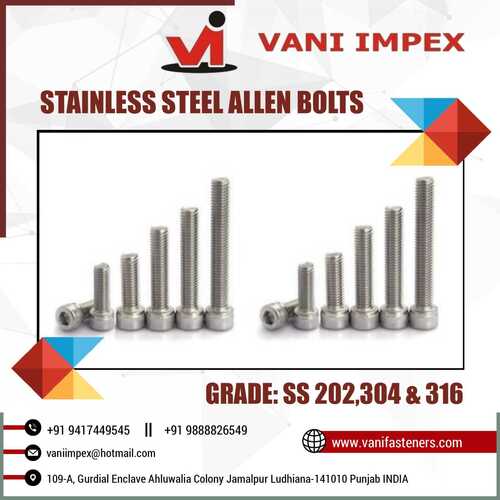

Exceptional Versatility and Material Quality

Machine screws are crafted from premium-grade materials including stainless steel, alloy steel, brass, and carbon steel, ensuring optimal durability and resistance to rust. With several grades and finishes, these fasteners are suitable for diverse environments and demanding mechanical applications.

Advanced Design Features for Secure Fastening

Engineered with precision-threading, anti-loosening mechanisms, and tolerance up to +/-0.02 mm, our screws deliver reliable performance. Choose from a variety of head shapes and drive types, making them ideal for numerous assembly requirements from general fastening to industrial machinery.

Comprehensive Packaging and Compliance

Available in boxes, bags, or bulk, these screws are RoHS compliant and manufactured as per DIN, ISO, ASTM, JIS, and BS standards. The packaging ensures safe handling and storage while compliance guarantees environmental responsibility and product reliability.

FAQ's of Machine Screws:

Q: How do I select the appropriate machine screw for my application?

A: Determine the required diameter (M2-M10), head type (Slotted, Phillips, Hex, etc.), material (stainless steel, alloy steel, brass, or carbon steel), and length (4-100 mm) based on your project. Also consider environmental conditions, load capacity, and required surface treatment for optimal performance.Q: What are the benefits of using machine screws with precision threading and anti-loosening features?

A: Precision-threaded and anti-loosening machine screws ensure secure fastening, minimize the risk of loosening due to vibration or thermal expansion, and maintain structural integrity even under heavy loads and varying temperatures.Q: Where are these machine screws typically used?

A: They are widely utilized in electrical assemblies, machinery installations, furniture manufacturing, construction projects, automotive applications, and general fastening tasks, thanks to their robust design and variety of specifications.Q: What is the process for ordering machine screws from a supplier or manufacturer in India?

A: Contact the distributor, exporter, manufacturer, supplier, or trader with your specific requirements, including screw dimensions, material, grade, quantity, and packaging type. The manufacturer will confirm details and process your order, ensuring timely delivery per your specifications.Q: When should I choose corrosion-resistant or specific surface-treated screws?

A: Select corrosion-resistant and surface-treated screws (zinc plated, nickel plated, black oxide, or chrome plated) when screws are exposed to moisture, chemicals, or outdoor environments to prolong lifespan and maintain appearance.Q: What usage guidelines should be followed for maximum screw performance?

A: Install machine screws using compatible tools based on drive type, apply recommended torque (up to 50 Nm), and ensure proper thread engagement. Follow manufacturer's instructions for load limits (up to 1200 kg) and suitable environmental conditions (-40C to +250C).Q: How does RoHS compliance benefit my application?

A: RoHS-compliant machine screws ensure environmental safety by restricting hazardous materials, making them ideal for sensitive applications in electronics, automotive, and export markets requiring strict regulatory adherence.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS