Heavy Duty Hsfg Washer

10 INR/Piece

Product Details:

- Grade 10.9, 8.8, 12.9

- Capacity Heavy Duty

- Corrosion Resistant Yes

- Thread Type Non-threaded Component

- Surface Treatment Hot Dip Galvanized, Zinc Plated, Black Oxide

- Load Capacity Suitable for high-stress applications

- Shape Round

- Click to View more

X

Heavy Duty Hsfg Washer Price And Quantity

- 10000 Piece

- 10 INR/Piece

Heavy Duty Hsfg Washer Product Specifications

- Suitable for high-stress applications

- Round

- HSFG Washer

- 3 mm to 10 mm

- Washer (Non-Driven)

- 38-45 HRC

- 0.25 mm

- Smooth, Polished, Black Finish

- IS 6649, DIN 6916, BS 4395 Part 1 & 2

- Heavy Duty

- 10.9, 8.8, 12.9

- High Strength, Heavy Load Capacity, Precision Machined

- Yes

- Non-threaded Component

- Hot Dip Galvanized, Zinc Plated, Black Oxide

- Min 1040 MPa

- Suitable for preloaded HSFG bolts

- Flat

- Structural Bolting, Bridges, Heavy Engineering

- M12 to M64

- Alloy Steel, Carbon Steel, Stainless Steel

Heavy Duty Hsfg Washer Trade Information

- All India

Product Description

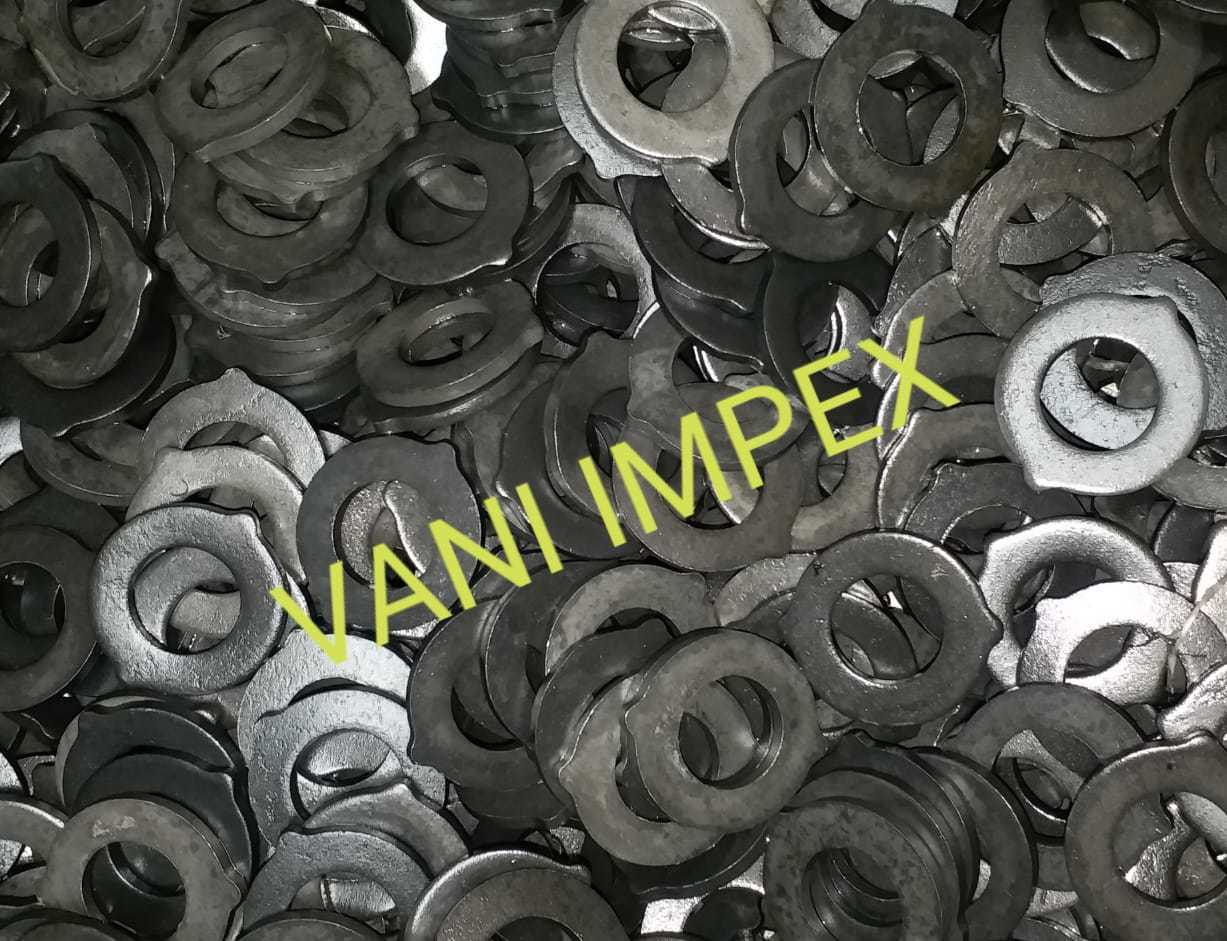

Hsfg Washer| Material | Alloy Steel |

| Surface Finish | Electroplated |

| Dimension/Size | M 16 to M 36 |

| Shape | Round |

| Packaging Type | Bags/Boxes |

| Brand | Vani |

| Diameter | M 16 to M 36 |

| Material Grade | 8.8 or 10.9 |

| I Deal In | New Only |

HSFG Washer IS 6649

VANI IMPEX is a leading firm in this industry, we are deeply engaged in offering a high-quality range of HSFG Washer.

Precision Engineering for Heavy Load Applications

Our HSFG washers undergo either forging or pressing, resulting in a dense, precision-machined component designed for structural bolting and high-stress environments. Each washer is burr-free with a smooth finish, providing uniform load distribution and enhanced durability in both indoor and outdoor installations, from complex bridgework to industrial buildings.

Comprehensive Compatibility and Standards

Compatible exclusively with preloaded HSFG bolts, our washers are manufactured to major global standards such as IS 6649, DIN 6916, and BS 4395 (Part 1 & 2). Users can choose from various sizes and grades, ensuring correct fitment for assemblies requiring maximum strength, accurate tolerances, and reliable corrosion protection.

Robust Protection and Versatile Usage

Every HSFG washer features a rust-proof surface treatment-hot dip galvanizing, zinc plating, or black oxide-to deliver lasting protection in both sheltered and exposed environments. Their high tensile strength and hardness ensure they excel under intense loads, making them indispensable for heavy engineering, bridge construction, and large-scale structural projects.

FAQ's of Heavy Duty Hsfg Washer:

Q: How are Heavy Duty HSFG Washers manufactured to ensure strength and reliability?

A: HSFG washers are produced through precision forging or pressing processes, which enhance density and mechanical properties. This manufacturing method guarantees high strength, accurate tolerances, and a burr-free edge, making them suitable for demanding structural and heavy engineering applications.Q: What applications are ideal for these HSFG washers?

A: They are perfect for structural bolting in bridges, heavy engineering, and construction projects where high strength, corrosion resistance, and precise load distribution are essential. Their design and standards compliance make them reliable in both outdoor and indoor environments.Q: When should I choose these washers for my project?

A: Select Heavy Duty HSFG washers when your assembly requires high load capacity, compliance with IS 6649, DIN 6916 or BS 4395, and superior corrosion resistance for challenging climates or high-stress structural joints involving HSFG bolts.Q: Where can these washers be used, and what environments are they suited for?

A: Designed for both indoor and outdoor environments, these washers are optimized for installations exposed to moisture, temperature variations, and aggressive conditions, such as bridges, factories, and infrastructure projects throughout India.Q: What are the advantages of the rust-proof and machined edge features?

A: A rust-proof coating extends washer lifespan and maintains performance in harsh environments. Precision-machined, burr-free edges prevent damage to assemblies, foster even load distribution, and simplify installation, making them sustainable for high-stress applications.Q: How do I ensure compatibility with my fasteners?

A: These washers are specifically engineered for preloaded HSFG bolts within M12 to M64 diameter ranges. Their sizing and standards adherence assure a precise fit and secure performance in heavy-duty bolted connections.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS