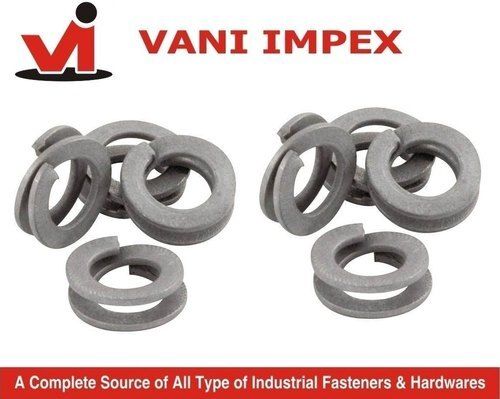

डबल कॉइल स्प्रिंग वॉशर

उत्पाद विवरण:

- टॉर्क Withstands high torque

- मोटाई 1 mm to 4 mm (varies with size)

- सतह का उपचार

- टेन्साइल स्ट्रेंथ High tensile

- कठोरता 41-48 HRC

- थ्रेड टाइप

- हेड टाइप No head (washer form)

- अधिक देखने के लिए क्लिक करें

X

डबल कॉइल स्प्रिंग वॉशर मूल्य और मात्रा

डबल कॉइल स्प्रिंग वॉशर उत्पाद की विशेषताएं

- Designed for dynamic and static loads

- Vibration resistance, reusable, high elasticity

- No head (washer form)

- Double Coil, Helical

- 41-48 HRC

- High tensile

- MS & Spring Steel

- Used to prevent loosening of bolted assemblies due to vibration

- 1 mm to 4 mm (varies with size)

- Withstands high torque

- Suitable for heavy duty applications

- IS 3063 / DIN 127 / DIN 7980

- Yes, depending on coating

- Bright, Black, Zinc Plated

- M3 to M24 (3 mm to 24 mm)

- ±0.1 mm

उत्पाद वर्णन

Double Coil Spring Washer

Double Coil Spring Washers is fabricated using superior quality materials and according to the standards of the company.

Specifications:

Size: (6mm - 20mm)

Material: MS, Spring Steel (Other Special Grade as per customer requirement)

Thickness : 8mm (0.25mm - 10mm)

Finish: Electro Zinc Plated (Other special coating as per customer requirement)

Additional Information:

Delivery Time: 25 - 30 DAYS

Packaging Details: 50 KGS GUNNY BAGS

Versatile and Durable Washer Solutions

Double Coil Spring Washers offer superior performance for critical sectors where vibration resistance and secure fastening are essential. With finishes including bright, black, and zinc plated, and compatibility with both mild and spring steel, these washers fit various industrial requirements. Their corrosion resistance and high elasticity ensure optimal function in both heavy-duty and high-torque applications, making them a go-to solution for engineers and technicians.

Customizable for Varied Industrial Demands

Meeting IS 3063, DIN 127, and DIN 7980 standards, these double coil washers can be tailored for size, material, finish, and packing type to address specific operational environments. Whether delivered in boxes or bags, and covering diameters from 3 mm to 24 mm, the washers provide reliability and efficiency for assemblies prone to vibration and load shifts.

FAQs of Double Coil Spring Washer:

Q: How does a double coil spring washer function to prevent loosening in bolted assemblies?

A: A double coil spring washer works by providing elastic tension when compressed between bolt head and substrate, maintaining consistent grip even under vibration. Its helical, double-coil design distributes load evenly, ensuring the fastening remains tight and resistant to loosening.Q: What applications are double coil spring washers typically used for?

A: These washers are predominantly used in applications where vibration or dynamic loads could cause fasteners to loosen, such as automotive, engineering, construction, and machinery industries. Their high elasticity and vibration resistance make them ideal for critical bolted connections.Q: When is it beneficial to choose a zinc plated or black oxide finish?

A: A zinc plated finish enhances corrosion resistance, making it suitable for outdoor or humid environments. Black oxide provides moderate corrosion protection and a non-reflective appearance, often preferred for indoor or low-moisture conditions. The choice depends on the applications environmental exposure.Q: Where are customizations available for double coil spring washers?

A: Customizations are available as per requirement, covering diameter (M3 to M24), thickness (1 mm to 4 mm), material (Mild Steel or Spring Steel), finish, and packing type (box or bag). These can be requested directly from the manufacturer or authorized distributor.Q: What manufacturing process is used for these washers and what are its advantages?

A: Double coil spring washers are produced using a cold-formed process, which involves shaping metal at room temperature. This method ensures precise dimensions, enhanced mechanical strength, consistent hardness, and superior surface finish, contributing to the washers durability and performance.Q: How can I determine the suitable size and grade for my application?

A: Selection depends on your bolted assemblys requirements, including bolt diameter, load intensity, and application environment. Sizes range from M3 to M24, with grades in MS and Spring Steelchoose spring steel for higher tensile strength or MS for standard use. Consulting technical documentation or the supplier can help with optimal selection.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें