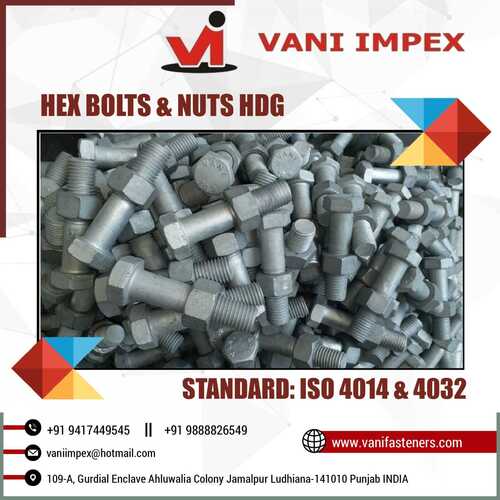

हेक्सागन स्क्रू आईएसओ 4014 ग्रेड 10.9

उत्पाद विवरण:

- थ्रेड टाइप

- संक्षारण प्रतिरोधी Yes

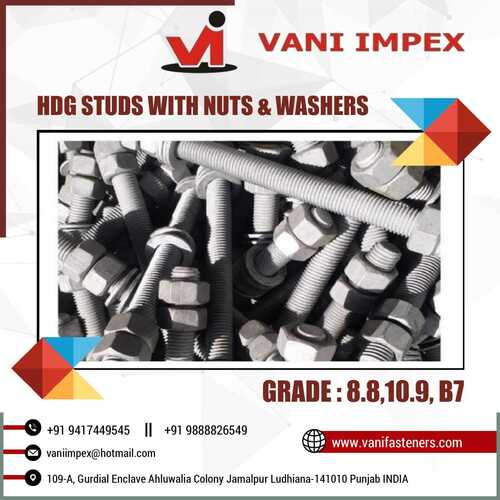

- फ़िनिश करें Zinc Plated, Black, Plain, Hot Dip Galvanized

- स्टैण्डर्ड ISO 4014

- सतह का उपचार

- फ़ीचर High Strength, Accurate Dimensions, Durable

- मोटाई As per ISO 4014 specification

- अधिक देखने के लिए क्लिक करें

X

हेक्सागन स्क्रू आईएसओ 4014 ग्रेड 10.9 मूल्य और मात्रा

हेक्सागन स्क्रू आईएसओ 4014 ग्रेड 10.9 उत्पाद की विशेषताएं

- Yes

- 32-39 HRC

- Hex

- Zinc Plated, Black, Plain, Hot Dip Galvanized

- ISO 4759-1 (Standard Fine)

- Hexagonal

- Hexagon

- ISO 4014

- Machine Building, Engineering, Construction, Automotive Industry

- High

- High Strength, Accurate Dimensions, Durable

- Suitable for high load requirements

- As per ISO 4014 specification

- 10.9

- 1040 MPa min

- M6 to M36

- Depends on diameter; e.g. M16 - up to 210 Nm

उत्पाद वर्णन

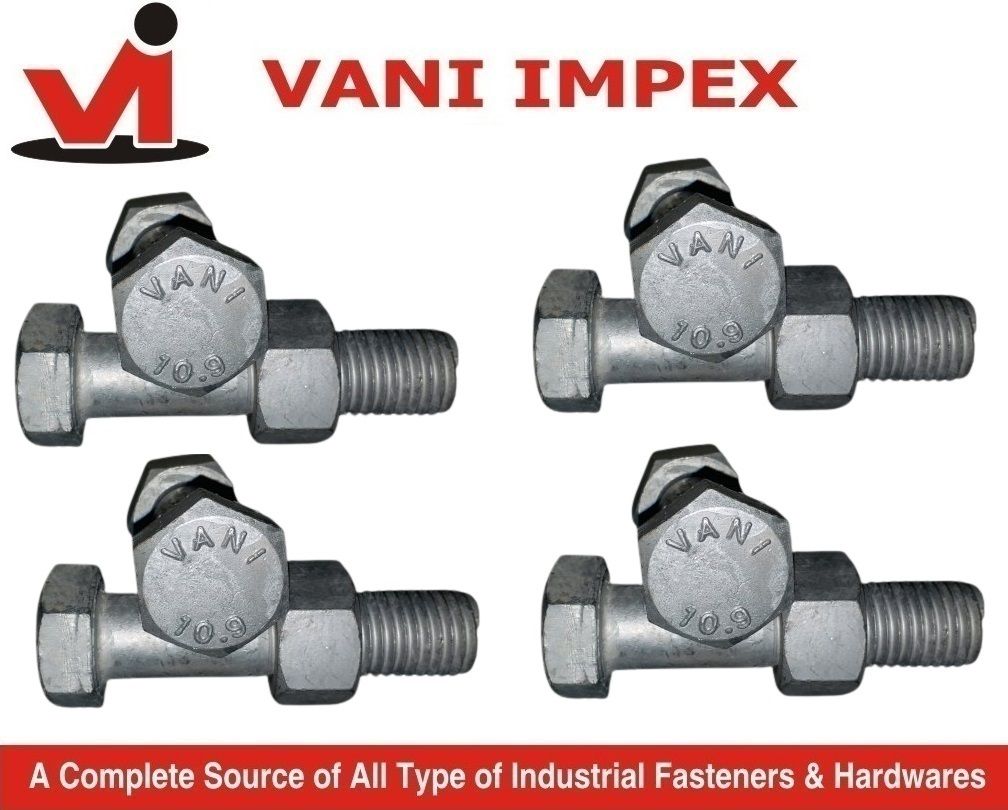

Hexagon Screw Iso 4014 Grade 10.9

| Size | M 8 to M 72 |

| Brand | VANI |

| Material | EN19 |

| Usage/Application | Various |

| Type Of Bolts | Hexagonal |

| Finish | Galvanized |

| Surface Finishing | Galvanized |

| Grade | 10.9 |

| Diameter | M 8 to M 72 |

| Packaging Type | Bags/Boxes |

| Coating | Hot Dip Galvanized |

| I Deal In | New Only |

Hexagonal Screw ISO 4014 Grade 10.9

We offer an exclusive range of High Tensile Bolts & Screws which are available in varied sizes and shapes. Manufactured using premium quality raw material, these are corrosion resistant and durable even in long run. अधिकover, these have High Tensile Strength owing to which these are highly popular in the market.

We have gained popularity all over the world owing to following significant features:

Corrosion Resistant

Durable Range

High Tensile Strength

Additional Information:

- Delivery Time: 30 DAYS

- Packaging Details: BAGS, BOXES

Exceptional Strength and Durability

Manufactured from Grade 10.9 alloy steel, these hexagon screws achieve a minimum tensile strength of 1040 MPa, ensuring outstanding load-carrying capacity and hardness (32-39 HRC), making them ideal for high-stress applications. Their reliable performance and dimensional accuracy meet ISO 4014 and ISO 4759-1 standards.

Versatile Application and Corrosion Resistance

Suitable for use across machine building, automotive, construction, and engineering sectors, the screws feature multiple surface treatments-including zinc plating, black oxide, and plain finishes-for excellent corrosion resistance. Their adaptability ensures dependable performance in a variety of installation environments.

Ready Stock and Custom Packaging

Available in lengths from 20 mm up to 200 mm and diameters M6 to M36, these screws can be provided in box, bag, or bulk packaging, based on customer requirements. With ready stock available through distributors, exporters, manufacturers, suppliers, and traders in India, quick and efficient supply is guaranteed.

FAQ's of Hexagon Screw Iso 4014 Grade 10.9:

Q: How can I select the appropriate Hexagon Screw ISO 4014 Grade 10.9 size for my application?

A: To choose the suitable size, consider the diameter (M6-M36) and length (20 mm-200 mm), the required thread pitch (e.g., M16 x 2.0), and the necessary tensile strength based on your project's load requirements. Always verify dimensional accuracy as per ISO 4014 specification.Q: What surface finishes are available, and how do they benefit the screw's performance?

A: The screws are offered in zinc plated, black oxide, plain, and hot dip galvanized finishes. These treatments enhance corrosion resistance, extending the fastener's lifespan, and providing reliable performance in diverse environmental conditions.Q: When should I use Grade 10.9 hexagon screws instead of lower-grade alternatives?

A: Grade 10.9 screws are recommended for applications demanding high strength and durability, such as heavy engineering, construction, and automotive assemblies where high tensile loads and harsh conditions are common.Q: Where can I source Hexagon Screw ISO 4014 Grade 10.9 in bulk quantities?

A: These screws are available in ready stock from authorized distributors, exporters, manufacturers, suppliers, and traders throughout India. They can be sourced in box, bag, or bulk packaging to suit your project needs.Q: What is the process for ensuring these screws are rust proof and corrosion resistant?

A: Rust and corrosion resistance are achieved through advanced surface treatments like zinc plating, black oxide, hot dip galvanizing, and strict adherence to material standards. These finishes provide a reliable barrier against environmental agents.Q: How are these hexagon screws typically used in industrial applications?

A: They are commonly utilized in assembling machines, construction frameworks, automotive components, and engineering projects where high strength, precise dimensions, and resistance to wear and corrosion are crucial for operational safety and longevity.Q: What are the key benefits of choosing Hexagon Screw ISO 4014 Grade 10.9 for my projects?

A: Key advantages include superior tensile strength (1040 MPa minimum), reliable corrosion protection, consistent quality, accurate dimensions, and compatibility with a wide range of demands from heavy industries, ensuring safety and long service life.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें